Essential Tips for Gasoline Engine Maintenance for Optimal Performance + Expert Guide + 17 Key Insights

Home » Essential Tips for Gasoline Engine Maintenance for Optimal Performance + Expert Guide + 17 Key Insights

Table of Contents

Introduction to Gasoline Engine Maintenance

Introduction to Gasoline Engine Maintenance

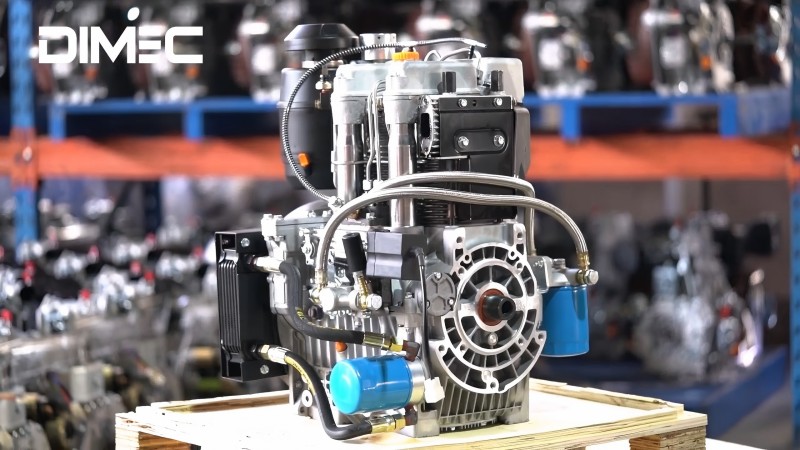

Gasoline engines power millions of vehicles, machines, and tools globally. Whether you’re driving a compact car, operating a portable generator, or using a lawnmower, your engine requires consistent upkeep. Neglecting maintenance leads to sluggish performance, unexpected breakdowns, and expensive repairs. But with just a little attention and a few routine checks, you can keep your engine purring like a cat.

Maintaining your gasoline engine isn’t just about saving money—it’s about reliability, safety, and efficiency. This guide breaks down the key strategies and insights you need to make your engine last longer and run better. So, buckle up—we’re about to take a deep dive into essential maintenance tips that every owner should know.

Why Proper Engine Maintenance Matters

Why Proper Engine Maintenance Matters

Extending Engine Life

Extending Engine Life

Think of your gasoline engine like the heart of your vehicle or equipment. Regular care ensures it keeps beating strong for years. Skipping maintenance can shave off thousands of miles from your engine’s life. Performing simple tasks like changing oil and replacing filters can extend your engine’s lifespan significantly.

Improving Fuel Efficiency

Improving Fuel Efficiency

When your engine is properly tuned and maintained, it burns fuel more efficiently. That means better mileage and more money saved at the pump. A dirty air filter or worn-out spark plugs can drastically reduce your fuel economy.

Reducing Emissions

Reducing Emissions

An engine that runs cleanly produces fewer emissions. Not only is this better for the environment, but in many regions, emissions compliance is required by law. Regular tune-ups help ensure your vehicle passes emissions tests and reduces its environmental impact.

Core Maintenance Practices Every Owner Should Follow

Core Maintenance Practices Every Owner Should Follow

Regular Oil Changes

Regular Oil Changes

Oil is the lifeblood of your engine. It lubricates moving parts, reduces friction, and prevents overheating. Most manufacturers recommend changing the oil every 3,000 to 5,000 miles or as specified in your owner’s manual.

Tips:

Use high-quality oil with the correct viscosity.

Always replace the oil filter when you change the oil.

Check your oil level monthly.

Replacing Air Filters

Replacing Air Filters

A clean air filter helps your engine breathe. Dirty filters choke performance and increase fuel consumption.

Signs you need to replace your air filter:

Decreased acceleration

Black smoke from exhaust

Strange engine sounds

Most air filters should be replaced every 12,000 to 15,000 miles.

Spark Plug Inspections

Spark Plug Inspections

Spark plugs ignite the fuel-air mixture in your engine. Faulty plugs can cause misfires, reduced power, and rough idling. Inspect them every 30,000 miles or as advised by your vehicle’s manual.

Pro Tip: Use a spark plug gap tool to ensure proper spacing.

Checking Fuel Lines and Hoses

Checking Fuel Lines and Hoses

Cracked or worn fuel lines can leak gasoline—a serious fire hazard. Inspect all visible lines for wear and replace them immediately if damage is found.

Seasonal Maintenance Tips

Seasonal Maintenance Tips

Preparing Your Engine for Summer Heat

Preparing Your Engine for Summer Heat

High temperatures can stress your engine. Here’s how to stay ahead of summer troubles:

Check and flush coolant levels

Inspect the radiator and hoses for leaks

Ensure proper battery charge (heat drains batteries faster)

Winterizing Your Gasoline Engine

Winterizing Your Gasoline Engine

Cold weather brings its own challenges:

Use winter-grade engine oil

Add fuel stabilizers if storing equipment

Keep your battery fully charged

Gasoline engines can be finicky in the cold, so a little prep goes a long way.

The Role of Fuel Quality in Engine Health

The Role of Fuel Quality in Engine Health

Choosing the Right Octane

Choosing the Right Octane

Not all gasoline is created equal. High-performance engines often require premium octane levels. Check your owner’s manual for octane recommendations.

Fact: Using the wrong octane can cause engine knocking, damaging pistons over time.

Avoiding Ethanol Damage

Avoiding Ethanol Damage

Many fuels contain ethanol, which can corrode engine components over time—especially in small engines or vehicles not driven frequently.

Tip: Use ethanol-free gasoline when possible, especially for equipment like lawnmowers or boats.

Understanding Engine Warning Signs

Understanding Engine Warning Signs

Gasoline engines usually give you clear warning signs when something’s not quite right. Recognizing and acting on these early indicators can help you prevent serious, costly problems down the line. Let’s break down the most common red flags and what they might mean for your engine’s health.

Engine Noise and Knocking

Engine Noise and Knocking

One of the most obvious signs that something’s wrong is a strange noise coming from under the hood. A light tapping or knocking sound could be a result of:

Worn-out spark plugs

Incorrect fuel octane level

Carbon buildup inside the combustion chamber

Failing bearings or pistons

If you hear persistent knocking or pinging, don’t ignore it. It may lead to major internal damage if left unchecked. Sometimes, simply using the right grade of gasoline or changing spark plugs can resolve the issue, but if the problem persists, a professional mechanic should inspect it.

Unusual Smoke from the Exhaust

Unusual Smoke from the Exhaust

The color of smoke coming out of your exhaust can tell you a lot:

| Smoke Color | Likely Cause |

|---|---|

| Blue smoke | Burning oil (often caused by worn valve seals or piston rings) |

| White smoke | Coolant leaking into the combustion chamber (possibly a blown head gasket) |

| Black smoke | Excess fuel burning (may indicate a rich fuel mixture or clogged air filter) |

Occasional smoke when starting a cold engine can be normal, but continuous or colored smoke is a definite red flag.

Dashboard Warning Lights

Dashboard Warning Lights

Modern vehicles and machinery are equipped with sophisticated electronic systems designed to monitor engine health. When a dashboard light comes on—especially the Check Engine light—it’s your vehicle’s way of asking for help.

Common engine-related warning lights include:

Check Engine

Oil Pressure Warning

Engine Overheating

Battery Charge Warning

What to do:

Use an OBD-II scanner to read the error codes (you can buy one or visit a local auto parts store).

Refer to your owner’s manual to understand the severity of the issue.

Address the problem quickly—especially if the light is flashing, which usually indicates an emergency.

DIY Maintenance vs. Professional Servicing

DIY Maintenance vs. Professional Servicing

Knowing what you can safely do on your own versus when to bring in a mechanic is a huge part of responsible engine ownership. Here’s how to strike the right balance.

When to DIY

When to DIY

Some basic maintenance tasks are safe, easy, and even satisfying to do yourself:

Changing oil and filters

Replacing spark plugs

Swapping air filters

Checking battery terminals

Inspecting belts and hoses

DIY Benefits:

Saves money

Builds mechanical knowledge

Allows immediate action on small issues

Just make sure to always follow your owner’s manual and wear proper safety gear.

When to See a Mechanic

When to See a Mechanic

Complex issues, especially those involving internal engine components, electrical systems, or fuel injection, are best left to trained professionals.

Visit a mechanic if:

The Check Engine light is flashing

Your engine is overheating

You hear grinding, knocking, or other alarming sounds

There’s a sudden drop in fuel efficiency

You’re dealing with transmission issues

Professionals have the tools and diagnostics to detect problems you might miss. Don’t hesitate to get a second opinion or request a detailed estimate before agreeing to major work.

Best Tools for Gasoline Engine Maintenance

Best Tools for Gasoline Engine Maintenance

Having the right tools in your garage can make engine maintenance faster, safer, and more accurate. Here’s a checklist of must-have gear and modern tech that can make a huge difference.

Must-Have Maintenance Gear

Must-Have Maintenance Gear

| Tool | Purpose |

|---|---|

| Oil filter wrench | Makes removing and replacing filters easier |

| Socket set | Essential for removing engine covers and spark plugs |

| Torque wrench | Ensures bolts are tightened to factory specs |

| Funnel and oil pan | Helps prevent messes during oil changes |

| Battery tester | Measures voltage and battery condition |

These are all affordable and widely available online or at hardware stores.

Diagnostic Tools and Apps

Diagnostic Tools and Apps

Today’s car and engine owners have access to smart tools that make diagnostics easier than ever:

OBD-II Scanners: Plug into your vehicle’s port to read trouble codes.

Mobile Apps (like Torque Pro or Car Scanner): Interpret those codes and even monitor real-time engine performance.

Digital Multimeter: Useful for testing electrical connections and battery voltage.

Technology gives you insight that used to be available only to certified mechanics—don’t underestimate its power!

FAQs About Gasoline Engine Maintenance

FAQs About Gasoline Engine Maintenance

1. How often should I change the oil in my gasoline engine?

Most engines benefit from oil changes every 3,000 to 5,000 miles, but always consult your owner’s manual. Modern synthetic oils may allow longer intervals.

2. Is premium gasoline better for my engine?

Only if your manufacturer recommends it. Using a higher octane than required won’t usually improve performance and may just cost you more at the pump.

3. Can bad spark plugs ruin my engine?

Yes. Bad plugs can cause misfires, poor fuel economy, and long-term damage to your catalytic converter if ignored.

4. What causes an engine to overheat?

Common causes include low coolant, a faulty thermostat, a broken water pump, or a leaking radiator. Address overheating immediately to avoid engine failure.

5. How do I know if my fuel filter needs replacing?

If your engine is sputtering, stalling, or struggling to start, a clogged fuel filter might be to blame. It’s a simple and affordable fix.

6. What’s the most important part of engine maintenance?

Routine oil changes are arguably the most critical, but every aspect—filters, spark plugs, and fuel quality—plays a role in engine longevity.

Conclusion and Final Thoughts

Conclusion and Final Thoughts

Gasoline engine maintenance doesn’t have to be complicated or intimidating. With the right knowledge, tools, and habits, you can keep your engine performing at its best for years. Whether you’re managing a car, motorcycle, generator, or small machinery, these tips are your roadmap to fewer breakdowns, better performance, and longer engine life.

Remember: consistency is key. Stick to a regular maintenance schedule, listen to your engine, and don’t be afraid to ask a pro for help when needed.

| Each use | First month or 20 hours | Every 3 months or 50 hours | Every 6 months or 100 hours | Every year or 300 hours | ||

|---|---|---|---|---|---|---|

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √☆ | |||||

| Sediment Cup | √ | |||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Spark arrester(optional parts) | Clean | √ | ||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel tank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

☆ Replace the paper element type only.

(1)Service more frequently when used in dusty areas.

(2)These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures.

Performed at every indicated month or operating hour interval, whichever comes first.

You May Also Like

Introduction to Gasoline Engine Maintenance

Introduction to Gasoline Engine Maintenance Why Proper Engine Maintenance Matters

Why Proper Engine Maintenance Matters Extending Engine Life

Extending Engine Life Improving Fuel Efficiency

Improving Fuel Efficiency Reducing Emissions

Reducing Emissions Regular Oil Changes

Regular Oil Changes Replacing Air Filters

Replacing Air Filters Spark Plug Inspections

Spark Plug Inspections Checking Fuel Lines and Hoses

Checking Fuel Lines and Hoses Seasonal Maintenance Tips

Seasonal Maintenance Tips Preparing Your Engine for Summer Heat

Preparing Your Engine for Summer Heat Winterizing Your Gasoline Engine

Winterizing Your Gasoline Engine The Role of Fuel Quality in Engine Health

The Role of Fuel Quality in Engine Health Avoiding Ethanol Damage

Avoiding Ethanol Damage Understanding Engine Warning Signs

Understanding Engine Warning Signs Engine Noise and Knocking

Engine Noise and Knocking Unusual Smoke from the Exhaust

Unusual Smoke from the Exhaust Dashboard Warning Lights

Dashboard Warning Lights When to See a Mechanic

When to See a Mechanic Best Tools for Gasoline Engine Maintenance

Best Tools for Gasoline Engine Maintenance Diagnostic Tools and Apps

Diagnostic Tools and Apps FAQs About Gasoline Engine Maintenance

FAQs About Gasoline Engine Maintenance Conclusion and Final Thoughts

Conclusion and Final Thoughts