Concrete Vibrator

Description

The basic principal of concrete vibration is to consolidate the mix by removing entrapped air. Vibration is a series of rapid compressive impulses which greatly reduces the surface friction between the various size particles of the mix. The result is the rearrangement of these particles into a denser mass. During the vibration process. Unwanted trapped air escapes to the surface.

A concrete vibrator uses an off-centered weight, which is spun as much as 10,000 times a minute, causing large air pockets in the concrete to disperse as the concrete is shaken. Especially in pours of low slump concrete, which uses minimal water, the use of a vibrator is essential to ensure that the concrete does not bubble or form holes. In cases where consumers will be looking at the finished concrete, as is common in some schools of design that employ concrete counters and floors, this tool will help create an even and attractive surface, rather than one that may be slightly ragged.

| Model | V28 | V32 | V38 | V45 | V50 | V60 | V70 |

|---|---|---|---|---|---|---|---|

| Poker diameter [mm] | 28 | 32 | 38 | 45 | 50 | 60 | 68 |

| Rotational speed [rpm] | 3000-3600 | ||||||

| Dia. of flexible hose [mm] | 25 | 30 | 30 | 30 | 36 | 36 | 36 |

| Dia. of flexible shaft [mm] | 8 | 10 | 10 | 10 | 13 | 13 | 13 |

| Length [m] | 6m (4-10m as optional) | ||||||

| N.W.[kg] | 9.5 | 12.5 | 13.5 | 14.5 | 19.5 | 23 | 24.5 |

| Submersible Pump Specification | ||

|---|---|---|

| Diameter [inch] | 2 | 3 |

| Length [m] | 6m (4-8m as optional) | |

| Delivery height [m] | 20 | 15 |

| N.W./G.W. [kg] | 4.6 | 4.4 |

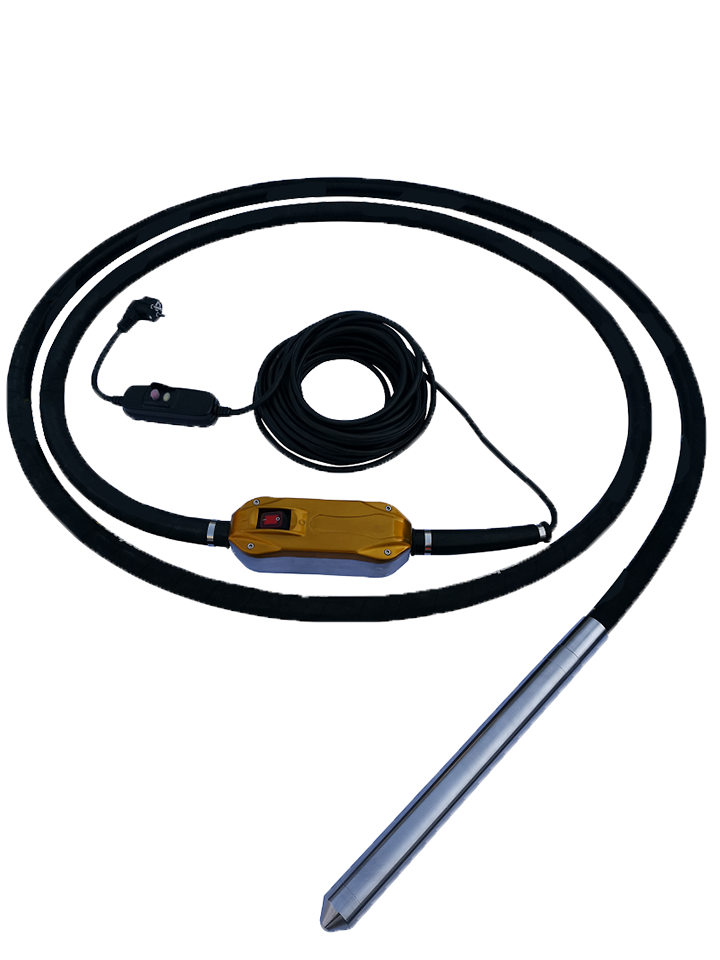

Portable concrete vibratory

| model | PME-PVH | PME-PVHS |

|---|---|---|

| Engine | Honda GX35 | Huasheng 140FA |

| Displacement [cc] | 35.8 | 31 |

| Engine power [HP] | 1.2 | 1 |

| Rated power [KW] | 0.95 | 0.65 |

| Speed [RPM] | 7000 | 9500 |

| Fuel tank capacity [L] | 0.63 | 0.6 |

| Oil tank capacity [L] | 0.1 | 0.07 |

Vibrator poker: V35; V38; V45

| Model | PME-BV |

|---|---|

| Engine | Honda / HuaSheng |

| Engine type | Air-cooled,single cylinder,4-stroke,petrol engine |

| Rotary speed [r/min] | 7500 |

| Vibrating poker diameter [mm] | V32x3m; V38x3m |

| N.W./G.W. [kg] | 8/10 |

Electric Vibrator Technical Data

| Model | PME-VE-1.1KW | PME-VE-1.5KW | PME-VE-2.2KW |

|---|---|---|---|

| Motor | Electric motor | Electric motor | Electric motor |

| Rated power [KW] | 1.1 | 1.5 | 2.2 |

| Voltage [V] | 220 | 220 | 220 |

| Frequency [Hz] | 50/60 | 50/60 | 50/60 |

| Phase | single phase | single phase | single phase |

| unloaded Speed [RPM] | 2850 | 2850 | 2850 |

| N.W./G.W. [kg] | 14/16 | 16/18 | 17/19 |

Vibrator poker: V28; V32; V38; V45; V50; V60; V70

Eccentric concrete vibrator

Strong plastic housing with double insulation and water-proof protection. Maintains a constant speed in the consolidation process regardless of slump. Requires less power consumption, using only the energy necessary for job completion. Vibrator with an ergonomic hand grip for operator comfort.

| Model | Electric Motor Power(kw) | vibrator head Dia.x length | Vibrating Frequency(vpm) | Rotational Speed(rpm) | Vibrating Amplitude(mm) | Diameter of Flexible Hose(mm) | Diameter of Flexible shaft(mm) | Length(M) | Weight(kg) |

|---|---|---|---|---|---|---|---|---|---|

| PME-EV-25 | 2.2 | 25*285 | 12000-18000 | 9500-14000 | 0.8 | 27 | 9 | 5-12m | 12 |

| PME-EV-32 | 2.2 | 32*366 | 12000-18000 | 9500-14000 | 1 | 27 | 9 | 5-12m | 13 |

| PME-EV-40 | 2.2 | 40*335 | 12000-18000 | 9500-14000 | 1.2 | 27 | 9 | 5-12m | 14 |

| PME-EV-48 | 2.2 | 48*335 | 12000-18000 | 9500-14000 | 1.3 | 27 | 9 | 5-12m | 14.5 |

| PME-EV-58 | 2.2 | 58*344 | 12000-18000 | 9500-14000 | 1.5 | 27 | 9 | 5-12m | 16 |

Vibrator poker: V25; V32; V40; V48; V58

| Model | PME-IH |

|---|---|

| Motor | Synchronous permanent magnet motor |

| Head Diameter | 40/45/50/60/65MM |

| Effective Diameter | 55/65/75/90/110CM |

| Performance/hour | 25/30/35/40/45m3 |

| Head Length | 40/42/43/44/50CM |

| Head Weight | 2.85/3.8/4.2/6.2/8.2KG |

| Frequency | 200-240Hz |

| Vibration rpm | 12000rpm |

| Input Voltage | 220V-240v/ (110-300v Available) |

| Current | 3.5/4.8/5.5/6/7.5A |

| Operation Noise | 7M<70decibel |

| Working Teamperature | -20℃~+100℃ |

| Head Hardness | HRC58-62° |

| Control Box | Die-casting, IP66 Slicone Gasket |

| Switch Box | Overheating/Overload Protecion, IP66 |

| Protection Hose | Custemized Rubber Material, 1800N tensile stength, |

| Cable | Customized Cable, Standard 15m, 1- 50m customizible |

| Protection | Overheating/Overload Protection |

| Water Proof | Vibrator Head IP68 |

| Upgrade Version | Module Design, Portable Handle, Remote Control,Flexible Design |

Application

Maintenance

Engine periodic maintenance schedule

| Each use | First month or 20 hours | Every 3 months or 50 hours | Every 6 months or 100 hours | Every year or 300 hours | ||

|---|---|---|---|---|---|---|

| Engine oil | Check level | √ | ||||

| Change | √ | √ | ||||

| Air cleaner | Check | √ | ||||

| Clean | √(1) | |||||

| Replace | √☆ | |||||

| Sediment Cup | √ | |||||

| Spark plug | Check-Clean | √ | ||||

| Replace | √ | |||||

| Spark arrester(optional parts) | Clean | √ | ||||

| Idle speed | Check-Adjust | √(2) | ||||

| Valve clearance | Check-Adjust | √(2) | ||||

| Fuel tank and strainer | Clean | √(2) | ||||

| Combustion chamber | Clean | After every 300 Hrs. (2) | ||||

| Fuel line | Check | Every 2 years (Replace if necessary) (2) | ||||

☆ Replace the paper element type only.

(1)Service more frequently when used in dusty areas.

(2)These items should be serviced by your servicing dealer unless you have the proper tools and are mechanically proficient. Refer to manual for service procedures.

Performed at every indicated month or operating hour interval, whichever comes first.