How Do Portable Diesel Generators Compare to Gasoline Generators?

Home » How Do Portable Diesel Generators Compare to Gasoline Generators?

Table of Contents

Introduction

Generators have become indispensable tools in our modern lives. Whether it’s for powering up homes during outages, providing electricity at construction sites, or ensuring a smooth camping trip, the importance of generators cannot be overstated. Among the most popular options are portable diesel and gasoline generators. But how do they stack up against each other? Let’s dive in and find out.

What are Portable Generators?

Portable generators are compact, movable units designed to provide electricity when and where it’s needed. They come in various sizes and power capacities, catering to different needs, from small household appliances to larger industrial equipment.

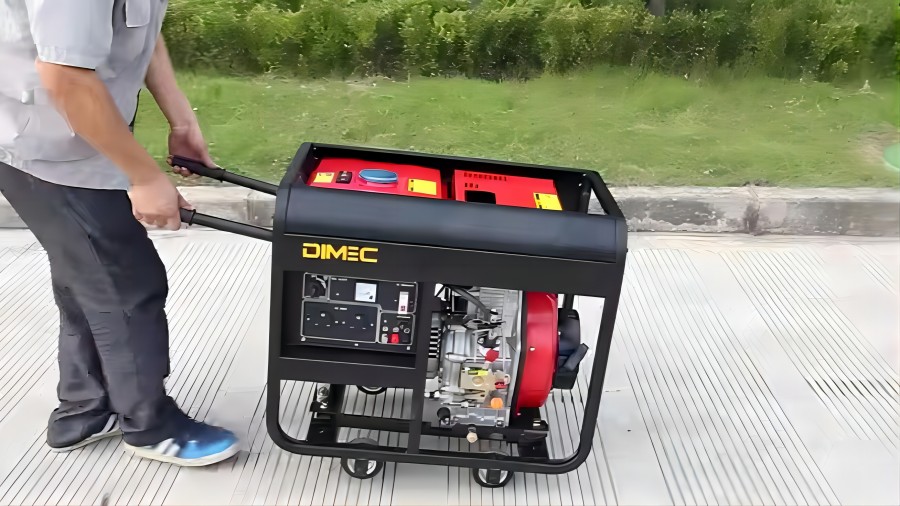

Portable Diesel Generators

How They Work

Portable single cylinder diesel generators operate by burning diesel fuel to power an internal combustion engine, which in turn drives an alternator to produce electricity. The process is efficient and produces a substantial amount of power.

Key Features

Two cylinder diesel generators are known for their robustness and longevity. They typically have a solid build and are designed to withstand harsh conditions, making them a favorite in industrial settings.

Common Uses

These generators are often used in construction sites, hospitals, and places where reliable power is crucial. Their ability to run for extended periods makes them ideal for continuous power supply needs.

Portable Gasoline Generators

How They Work

Gasoline generators function similarly to their diesel counterparts but use gasoline as the fuel source. The gasoline ignites within the engine, driving the alternator to generate electricity.

Key Features

Gasoline generators are generally more lightweight and easier to start than diesel generators. They are also typically less expensive upfront, making them a popular choice for residential use.

Common Uses

These generators are commonly used for home backup power, recreational activities like camping, and small-scale construction projects.

Performance Comparison

Power Output

Diesel generators generally offer higher power output and are more suitable for heavy-duty applications. Gasoline generators, while effective, are better suited for lighter, less demanding tasks.

Fuel Efficiency

Diesel generators are more fuel-efficient, offering longer run times per gallon of fuel compared to gasoline generators. This efficiency makes diesel a preferred choice for extended use.

Durability and Reliability

Diesel engines are built to last and often require less frequent maintenance than gasoline engines. This durability translates to higher reliability, especially in demanding environments.

Cost Analysis

Initial Purchase Price

Gasoline generators are typically cheaper to purchase initially. Diesel generators, although more expensive upfront, often justify their cost through longevity and lower fuel consumption.

Maintenance and Operational Costs

Diesel generators tend to have lower operational costs due to their fuel efficiency and durability. However, they may require more specialized maintenance services, which can add to the overall cost.

Environmental Impact

Emissions

Diesel generators produce more particulate matter and NOx emissions compared to gasoline generators, making them less environmentally friendly. However, advancements in technology are helping to reduce these emissions.

Fuel Consumption

Diesel engines are more fuel-efficient, reducing the amount of fuel burned and the associated emissions over time.

Noise Levels

Diesel Generators

Diesel generators are generally noisier due to the combustion process and the mechanical nature of diesel engines. However, modern models have incorporated noise-reduction technologies.

Gasoline Generators

Gasoline generators are typically quieter, making them more suitable for residential areas or recreational use where noise is a concern.

Portability and Convenience

Size and Weight

Gasoline generators are usually lighter and more compact, enhancing their portability. Diesel generators, being heavier and larger, may pose challenges in terms of transportation.

Ease of Transportation

Gasoline generators score higher in terms of ease of transport. Their lighter weight and compact size make them easier to move and store.

Safety Considerations

Diesel Generators

Diesel fuel is less flammable compared to gasoline, reducing the risk of fire. Diesel generators also tend to have more robust safety features.

Gasoline Generators

Gasoline is highly flammable, necessitating careful storage and handling. Gasoline generators must be used with caution to prevent accidents.

Pros and Cons of Diesel Generators

Advantages

- Higher fuel efficiency

- Longer lifespan

- More reliable in demanding conditions

Disadvantages

- Higher initial cost

- Noisier operation

- Heavier and less portable

Pros and Cons of Gasoline Generators

Advantages

- Lower initial cost

- Quieter operation

- Lighter and more portable

Disadvantages

- Higher fuel consumption

- Shorter lifespan

- Greater fire risk due to gasoline’s flammability

Best Use Cases

Diesel Generators

Diesel generators excel in industrial settings, large construction sites, and any situation requiring continuous, reliable power over long periods.

Gasoline Generators

Gasoline generators are perfect for home backup power, camping trips, and small-scale projects where portability and ease of use are paramount.

Choosing the Right Generator for Your Needs

Factors to Consider

- Power requirements: Assess the power needs of your appliances or equipment.

- Frequency of use: Determine how often you’ll need the generator.

- Portability: Consider the importance of easy transportation and storage.

- Budget: Balance initial cost with long-term operational expenses.

Personal and Situational Requirements

Evaluate your specific situation to choose the generator that best fits your needs. For instance, if you need a generator for occasional use during power outages, a gasoline generator might be ideal. Conversely, if you’re looking for a reliable power source for a construction site, a diesel generator could be the better option.

Conclusion

When comparing portable diesel generators to gasoline generators, it boils down to your specific needs and circumstances. Diesel generators offer durability, efficiency, and high power output, making them ideal for industrial and heavy-duty applications. Gasoline generators, on the other hand, are more affordable, quieter, and easier to transport, making them perfect for residential use and recreational activities. Carefully consider the pros and cons of each type to make an informed decision that aligns with your requirements.

FAQs

What is the lifespan of a portable diesel generator?

A portable diesel generator can last between 10,000 to 30,000 hours, depending on maintenance and usage conditions.

Can I use a portable generator indoors?

No, portable generators should never be used indoors due to the risk of carbon monoxide poisoning. Always use them in well-ventilated outdoor areas.

How often should I perform maintenance on my generator?

Regular maintenance should be performed every 100-200 hours of operation or as recommended by the manufacturer.

Are there any special storage requirements for diesel or gasoline generators?

Yes, both types of generators should be stored in a cool, dry place. Diesel fuel has a longer shelf life but can still degrade, so proper fuel storage practices are essential.

What are the best brands for portable diesel and gasoline generators?

Top brands include Honda, Yamaha, Generac, and Cummins for gasoline generators, and brands like Caterpillar, Kohler, and Perkins for diesel generators.

You May Also Like