Diesel Engine maintain Mastery: 15 Power Tips to Prolong Engine Life

- Diesel Engine maintain

- 15/07/2022

Главная " Diesel Engine maintain Mastery: 15 Power Tips to Prolong Engine Life

Оглавление

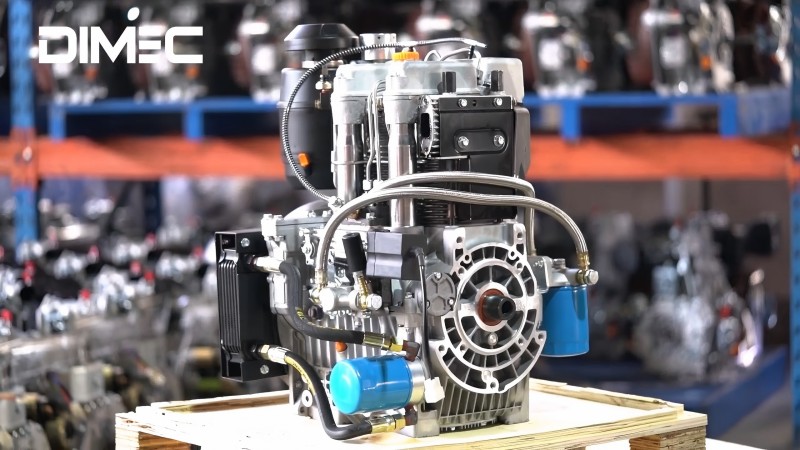

Introduction to Diesel Engine Maintenance

Diesel engines are known for their durability and reliability—but only when they’re properly maintained. Whether you operate a commercial fleet, run a diesel-powered generator, or simply drive a diesel car or truck, understanding and performing regular maintenance is critical. This guide provides a comprehensive approach to diesel engine care, with 15 power-packed tips to help extend the life of your engine and maximize efficiency.

Why Diesel Engine Maintenance Matters

Proper diesel engine maintenance isn’t just good practice—it’s essential.

The Cost of Neglect

Skipping routine maintenance can lead to catastrophic failures, costly repairs, and even complete engine replacement. Small issues like clogged fuel filters or dirty oil can spiral into major problems.

Longevity and Performance

Diesel engines are built to last, often surpassing gasoline engines in lifespan—but only if they’re taken care of. Routine upkeep not only extends lifespan but also maintains fuel efficiency and power output.

Tip #1: Stick to a Regular Maintenance Schedule

A maintenance calendar is your best friend. Follow manufacturer guidelines for service intervals, including oil changes, filter replacements, and system inspections.

| Service Item | Suggested Interval |

|---|---|

| Oil Change | Every 5,000–7,500 miles |

| Fuel Filter Change | Every 10,000–15,000 miles |

| Air Filter Check | Every 12,000–15,000 miles |

| Coolant Replacement | Every 2 years |

Setting reminders or using fleet management software can help keep everything on track.

Tip #2: Change the Oil and Oil Filter Consistently

Oil is the lifeblood of your engine. It lubricates moving parts, reduces friction, and helps keep the engine cool. Dirty or low oil can cause excessive wear or even engine seizure.

Why It Matters:

Prevents sludge buildup

Enhances engine performance

Protects moving parts from wear

Make sure to use high-quality diesel engine oil that meets your manufacturer’s specifications.

Tip #3: Monitor and Replace Fuel Filters

Fuel quality directly affects your engine’s performance. Over time, contaminants like dirt, water, and algae can accumulate in your fuel tank. A clean fuel filter ensures these don’t reach your engine.

Совет профессионала: If your engine sputters, loses power, or starts hard—your fuel filter could be the culprit.

Tip #4: Keep the Cooling System Clean

Diesel engines run hot, especially under heavy loads. Overheating can warp engine components and lead to failure.

Maintenance Steps:

Flush the coolant system periodically

Inspect the radiator and hoses

Ensure the coolant is topped off and clean

Use a coolant that meets OEM standards and is suited for your engine’s operating environment.

Tip #5: Check and Maintain the Air Filter

A clogged air filter suffocates your engine, reducing efficiency and increasing fuel consumption.

When to Replace:

When driving in dusty or off-road conditions

If fuel economy drops noticeably

At regular service intervals or sooner if dirty

A clean air filter improves combustion and reduces emissions.

Tip #6: Use the Right Diesel Fuel

Not all diesel fuels are created equal. Using low-quality or contaminated diesel can clog injectors, damage fuel pumps, and increase emissions.

Tips:

Buy fuel from reputable sources

Consider using diesel additives to improve cetane rating and prevent gelling in cold climates

Store fuel properly if unused for long periods

Tip #7: Inspect the Glow Plugs and Injectors

Glow plugs help start the engine in cold weather. Faulty plugs can lead to hard starts and misfires.

Fuel injectors control the amount and timing of fuel delivery. Dirty or worn injectors cause poor performance and fuel waste.

Check for:

White smoke during startup

Rough idling or misfiring

Increased fuel consumption

Tip #8: Keep an Eye on Exhaust and Emissions

Modern diesel engines use emission control systems like DPFs (diesel particulate filters) and EGR valves. If these get clogged, performance tanks.

Watch for:

Increased black smoke

Warning lights for emissions

Reduced fuel efficiency

Regular regeneration cycles and using low-sulfur fuel help maintain emission systems.

Tip #9: Monitor Belt and Hose Conditions

Belts and hoses might seem minor compared to pistons or injectors, but a worn-out belt can leave your engine dead in the water.

What to Watch:

Cracks, fraying, or visible wear on belts

Soft, brittle, or bulging hoses

Leaks around hose connections

Inspect these components at each service interval. Replacing a $20 belt now is far better than paying for a $2,000 engine repair later.

Tip #10: Keep the Battery in Good Shape

Even though diesel engines don’t rely on spark plugs like gasoline engines, they still need strong batteries to power the glow plugs and starter motor.

Battery Maintenance Tips:

Check terminals for corrosion and clean regularly

Ensure tight, clean connections

Test battery voltage and charge status, especially in cold months

If your battery struggles to start the engine, don’t wait—get it tested or replaced.

Tip #11: Regularly Check Fluid Levels

Beyond engine oil and coolant, diesel engines rely on multiple fluids to operate efficiently.

Fluids to Monitor:

Brake fluid

Transmission fluid

Power steering fluid

Windshield washer fluid

Low or dirty fluids can impair vehicle performance or cause safety issues. Always top off with the appropriate type and grade.

Tip #12: Watch for Leaks and Unusual Noises

Engines often “talk” before breaking down. Small leaks or odd sounds can signal major issues in the making.

Common Symptoms:

Oil spots beneath the engine

Coolant puddles or steam from the hood

Hissing, knocking, or whining noises

Unusual vibrations or smells

Early detection allows you to fix issues before they spiral out of control.

Tip #13: Don’t Ignore Warning Lights

Modern diesel engines are equipped with sophisticated sensors and warning systems. When a dashboard light turns on, it’s not just for show—it’s a call to action.

Common Warning Lights:

Check engine light

Glow plug indicator

DEF fluid level warning

DPF regeneration alert

Use an OBD-II scanner or visit a technician to identify the issue quickly and prevent further damage.

Tip #14: Let the Engine Warm Up Before Heavy Use

Cold starts are tough on diesel engines. Giving your engine a few minutes to warm up allows oil to circulate and reach operating viscosity.

Why It Matters:

Reduces engine wear

Helps reach optimal combustion temperature

Prevents cold-weather starting problems

In freezing temperatures, consider using a block heater to pre-warm the engine.

Tip #15: Keep Your Engine Clean

A clean engine is easier to inspect and helps prevent overheating by allowing heat to dissipate properly.

Cleaning Tips:

Use a degreaser to remove oil and dirt buildup

Protect electrical components with plastic covers during cleaning

Avoid high-pressure washing directly on sensors or delicate parts

A clean engine also makes it easier to spot leaks or other early signs of trouble.

Часто задаваемые вопросы (FAQ)

1. How often should I service my diesel engine?

Typically, every 5,000–7,500 miles, but it depends on usage and manufacturer guidelines. Heavy-duty or off-road use may require more frequent service.

2. What type of oil should I use in my diesel engine?

Always use oil that meets your engine manufacturer’s specs. For example, many diesel engines require oils that meet API CK-4 or CJ-4 standards.

3. Can I use regular fuel additives?

Yes, especially during winter or when storing fuel. Look for additives that improve cetane levels, prevent gelling, and clean injectors.

4. How do I know if my diesel injectors are bad?

Symptoms include rough idling, white smoke, poor fuel economy, and decreased power. A professional diagnostic can confirm the issue.

5. Why is my diesel engine blowing black smoke?

Usually due to incomplete combustion—this can result from dirty air filters, faulty injectors, or excessive fuel delivery.

6. What’s the benefit of letting a diesel engine idle before shutting it off?

Letting it idle for a minute or two cools the turbocharger and prevents oil from burning onto hot components—especially after heavy use.

Заключение

Maintaining your diesel engine is more than a checklist—it’s a long-term investment in performance, reliability, and peace of mind. By following these 15 essential maintenance tips, you’ll keep your engine running stronger, longer, and with fewer costly surprises. Whether you’re a professional fleet manager or a diesel vehicle owner, proactive care is your best defense against breakdowns and downtime.

Want to learn even more? Check out the Diesel Technology Forum for additional resources on diesel care, technology, and news.

| Каждое использование | 1 месяц или 20 часов. | Каждые 3 месяца или 100 часов. | Каждые 6 месяцев или 500 часов. | Каждый год или 1000 часов. | |

|---|---|---|---|---|---|

| Проверьте и залейте топливо | √ | ||||

| Сброс топлива | √ | ||||

| Проверьте и залейте масло | √ | ||||

| Проверьте утечку масла | √ | ||||

| Проверьте и затяните внешнюю фурнитуру | √ | ||||

| Замена масла | √ | √ | |||

| Замените масляный фильтр | √ | ||||

| Замените элемент воздушного фильтра | √(1) | ||||

| Очистите топливный фильтр | √(2)(изменение) | ||||

| Проверьте масляный насос высокого давления | √(2) | ||||

| Проверьте форсунку | √(2) | ||||

| Проверьте топливную трубку | √(2) | ||||

| Отрегулируйте зазоры на входе и выходе воздуха | √(2) | √(2) | |||

| Забор воздуха для шлифования и затвор для отвода воздуха | √(2) | ||||

| Замените поршневое кольцо | √(2) | ||||

| Проверьте электролитический раствор аккумулятора | Каждый месяц | ||||

| Проверьте электрическую щетку и скользящее кольцо | √(2) | ||||

| Проверьте сопротивление изоляции | Остановка работы более 10 дней | ||||

Выполняется через каждые указанные месяцы или часы работы, в зависимости от того, что наступит раньше.

(1) При использовании в пыльных помещениях обслуживайте чаще.

(2) Эти элементы должны обслуживаться вашим дилером, если у вас нет соответствующих инструментов и механических навыков. Порядок обслуживания см. в руководстве.

Вам также может понравиться