Vibratory Rammer Machine PME-RM80

When you are looking for a vibratory rammer machine, we can assist you in selecting the most suitable pilon de bourrage pour votre entreprise.

Vibratory Rammer Machine PME-RM80

The PME-RM80 Pilon vibrant Machine is a powerful and reliable solution for soil compaction, designed to meet the demands of professional contractors and construction projects. Featuring a 345 x 285 mm plate and a tamping force of 10 KN, it achieves a leap height of 65 mm, making it an efficient tool for compacting soils in a variety of applications.

De puissantes performances

The PME-RM80 offers a choice of engine options, including Honda, Robin, Loncin, and diesel engines, ensuring versatility and reliability for various operational needs. These air-cooled, single-cylinder, 4-stroke engines are paired with a 2.8 L fuel tank, providing extended operation time and consistent performance. Operating at a frequency of 650 VPM, this vibratory rammer delivers steady impact, effectively compacting cohesive soils like clay and silt as well as mixed soils.

Application polyvalente

This vibratory rammer is designed to excel in confined spaces and areas requiring precise compaction. Whether preparing foundations, compacting trenches, or stabilizing soil for subgrades, the PME-RM80 is versatile enough to handle a range of tasks. Its moderate tamping force and focused impact make it an excellent choice for cohesive and mixed soil types, ensuring stability and strength for construction projects.

Construit pour durer

Durability is at the heart of the PME-RM80’s design. Constructed with premium materials, it is built to endure the challenges of continuous use in tough environments. The robust build ensures consistent performance, making it suitable for applications such as base preparation, pipeline compaction, and landscaping, while delivering dependable results over time.

Applications

- Compaction des tranchées et des services publics

- Préparation des fondations et des semelles

- Subgrade and Base Layer Compaction

- Semelles des murs de soutènement

- Road Repair and Patchwork

- Compaction des sols cohésifs et mixtes (par exemple, argile, limon)

- Soil Stabilization for Landscaping and Construction

- Compactage de zones confinées ou étroites

With its efficient tamping force, versatile engine options, and durable construction, the PME-RM80 Vibratory Rammer Machine is a trusted companion for construction professionals and rental services, providing reliable and effective soil compaction for a variety of projects.

Principales spécifications

| Modèle | Vibratory Rammer Machine PME-RM80 |

|---|---|

| Moteur | Honda / Robin / Loncin / Moteur diesel |

| Type de moteur | Moteur à essence / moteur diesel refroidi par air, monocylindre, 4 temps |

| Réservoir de carburant [L] | 2.8 |

| Hauteur de saut [mm] | 65 |

| Fréquence [VPM] | 650 |

| Force d'appui [KN] | 10 |

| Taille de la plaque (LxL) [cm] | 345x285 |

| Poids net / poids brut [kg] | 80/90 |

| Emballage (LxLxH) [cm] | 75x43x115 |

AVANTAGE

Réservoir de carburant renforcé

Le réservoir de carburant est fabriqué à partir de matériaux résistants aux chocs et de raccords sûrs, ce qui garantit un stockage fiable du carburant et évite les fuites dans des conditions de travail difficiles.

Moteur robuste

Équipé d'un moteur puissant et fiable de marques renommées, il garantit des performances fluides, un faible niveau sonore, un entretien minimal et une grande efficacité énergétique.

Système avancé d'absorption des chocs

La conception améliorée de l'absorption des chocs réduit considérablement les vibrations dans les mains de l'opérateur, offrant ainsi une expérience d'utilisation confortable et contrôlée.

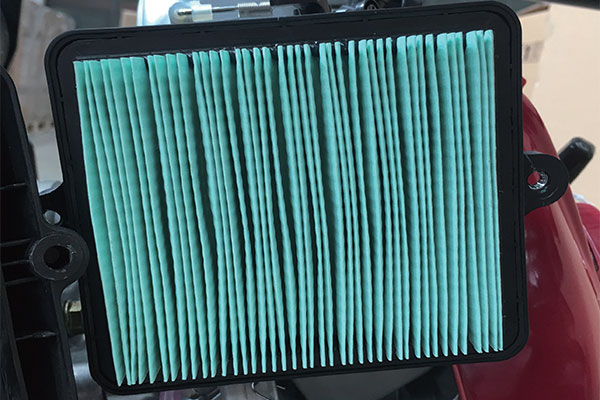

Système efficace de purification de l'air

Un système de filtre à air sophistiqué retient efficacement la poussière et les débris, ce qui permet de garder le moteur plus propre et de réduire les besoins d'entretien pour prolonger la durée de vie des performances.

Soufflet pliant en polyuréthane

Le soufflet en polyuréthane flexible à haute résistance offre une durabilité et une longévité accrues, résistant à la fissuration et à la déformation même en cas d'utilisation intensive.

Plaque de base durable

Une plaque de base renforcée en acier de haute qualité, conçue pour une stabilité maximale et une efficacité de compactage optimale sur différents terrains.

QUESTIONS ET RÉPONSES

A vibratory rammer is primarily used for soil compaction in confined or challenging spaces, such as trenches, edges, and corners. It ensures a stable and dense base for construction projects, roadways, and landscaping tasks.

Vibratory rammers are designed for deeper compaction and are more effective in cohesive soils like clay. They are suitable for tight spaces. Plate compactors, on the other hand, work better on granular soils such as sand and gravel and are ideal for covering larger surface areas.

Yes, vibratory rammers can be used on various soil types, but their performance is optimized for cohesive and semi-cohesive soils. For granular soils, a plate compactor may provide better results.

Routine maintenance includes checking and changing engine oil, cleaning the air filter, inspecting the footplate, and tightening bolts. Following the manufacturer’s guidelines ensures longevity and consistent performance.

Electric rammers are generally quieter and eco-friendlier, but they may not deliver the same level of power as gas-powered models for heavy-duty tasks. However, advancements in technology are closing this performance gap.

Consider factors such as soil type, project scale, frequency of use, and budget. Gas-powered rammers are better for outdoor and remote areas, while electric models suit indoor or urban environments. Evaluate the machine’s size, weight, and features before making a purchase.

Autres produits similaires

Scie à béton PME-Q400

Scie à béton PME-Q350

Scie routière PME-Q300

Rouleau Vibro Ride On PME-R6000

Rouleau compacteur routier PME-R3500

Rouleau de chantier PME-R3000

Plus de 20 ans d'expérience

Fabricant de machines de construction

Fabricant professionnel de petites machines de construction, les principaux produits comprennent le compacteur à plaque, pilon de bourragerouleau compresseur, scie à sol, vibrateur de béton, générateur, etc.

Pilon de bourrage

Les pilonneuses jouent un rôle essentiel dans la construction moderne. Elles sont largement utilisées pour leur efficacité à compacter la terre, le gravier et d'autres matériaux granulaires. Connues pour leur mouvement à fort impact, les pilonneuses stabilisent le sol, fournissant des fondations solides pour les routes, les chemins et les bâtiments. Elles fournissent les surfaces compactées nécessaires à diverses applications de construction. Leur force d'impact puissante et leur polyvalence en font un choix de premier ordre pour les entrepreneurs et les constructeurs, assurant des fondations solides et fiables dans chaque projet.

The Role of Vibratory Rammer Machines in Soil Compaction

Introduction to Vibratory Rammers and Their Importance in Soil Compaction

Vibratory rammers are indispensable tools in modern construction and landscaping, known for their ability to compact soil efficiently and reliably. These machines are engineered to apply focused pressure and vibration, ensuring a denser and more stable soil base. Whether it’s preparing a foundation for a building or ensuring a robust roadbed, vibratory rammers provide unmatched performance, especially in confined spaces or on challenging terrain.

Understanding Soil Compaction

Soil compaction refers to the process of increasing soil density by reducing air gaps between soil particles. This results in a firmer and more stable base, which is essential in various applications such as construction, agriculture, and landscaping. Compaction enhances soil strength and load-bearing capacity, preventing issues like settlement or shifting that can compromise structural integrity.

Pourquoi le compactage du sol est-il important ?

Compacted soil provides a reliable foundation for buildings, roads, and other structures. Proper compaction minimizes the risk of structural damage caused by uneven settling over time. In agriculture, it helps create an even surface for planting while reducing erosion and improving water retention. Without adequate compaction, projects can face costly repairs, reduced efficiency, and safety hazards.

Facteurs affectant le compactage du sol

Plusieurs facteurs influencent l'efficacité du compactage du sol, notamment

- Type de sol : Cohesive soils like clay require different compaction methods compared to granular soils like sand.

- Moisture Content: Ideal moisture levels enhance compaction, while overly wet or dry soils are harder to compact.

- Compaction Equipment: The right tools, such as vibratory rammers, ensure optimal results depending on the project’s needs.

Tools Used for Soil Compaction

Soil compaction relies on specialized equipment tailored to project requirements. The choice of tools depends on factors such as the size of the area, soil type, and compaction depth.

Common Equipment for Soil Compaction

- Vibratory Rammers: Perfect for confined spaces and cohesive soils, these tools deliver high-impact force and vibration to achieve deep compaction.

- Compacteurs à plaques : Ideal for flat, open areas, they are efficient for granular soils like gravel and sand.

- Rollers: Used for large-scale projects, including roads and highways, rollers are unmatched in covering extensive areas quickly.

Pilonneurs vibrants et compacteurs à plaque

While vibratory rammers excel in precision and depth, plate compactors are better suited for surface-level compaction. Rammers are more versatile in challenging terrains and tight spaces, whereas compactors offer faster performance on open ground.

Anatomy of a Vibratory Rammer Machine

A vibratory rammer comprises several essential components, each designed for maximum efficiency and durability. Understanding these parts is key to operating and maintaining the equipment.

Key Components

- Engine: Powers the machine, typically available in gas or electric variants.

- Footplate: The part that contacts the soil, delivering compaction force directly to the ground.

- Handle: Ergonomically designed for operator control and ease of movement.

- Shock Absorbers: Reduce vibrations transmitted to the operator, improving comfort and safety.

How Vibratory Rammers Work

The engine generates power, driving the footplate to repeatedly strike the ground. This combination of impact and vibration ensures that soil particles are compacted tightly, resulting in a dense and stable base.

Advantages of Vibratory Rammer Machines

Vibratory rammers are favored for their efficiency and adaptability. Their compact design and powerful performance make them an indispensable tool for various applications.

Key Benefits

- Compaction de précision : Ideal for trenches, corners, and other confined spaces where larger equipment cannot operate.

- Adaptability: Handles a wide range of soil types, including cohesive and wet soils.

- Mobilité : Lightweight and easy to maneuver, even in difficult terrains.

- Rentable : Reduces the time and effort required for soil preparation, saving labor costs in the long run.

Applications of Vibratory Rammer Machines

The versatility of vibratory rammers makes them suitable for diverse applications across industries. From construction sites to landscaping projects, these machines deliver reliable results.

In Construction

- Preparing roadbeds for pavement.

- Compacting soil in trenches for utility installations.

- Strengthening foundations for buildings and retaining walls.

In Landscaping

- Creating stable pathways and garden borders.

- Leveling soil for turf installation.

Their ability to tackle both small-scale and large-scale tasks ensures they remain a staple in professional settings.

Types of Vibratory Rammer Machines

Vibratory rammers come in various types, each designed to cater to specific needs. Whether you’re tackling a large construction project or a small landscaping job, selecting the right model ensures optimal results.

Gas-Powered Vibratory Rammer Machines

These are the most common type and are powered by gasoline engines. They are portable, powerful, and suitable for outdoor projects where access to electricity might be limited. Their robust design makes them ideal for compacting cohesive soils in trenches and roadbeds.

Avantages :

- High mobility.

- Reliable for heavy-duty tasks.

- Suitable for remote areas without electrical access.

Considerations:

- Regular maintenance of the engine is required.

- Emissions and noise levels can be higher compared to electric models.

Electric Vibratory Rammer Machines

Electric rammers are increasingly popular due to their environmental benefits. They are quieter, require less maintenance, and produce no emissions, making them ideal for indoor or urban use.

Avantages :

- Eco-friendly and low noise levels.

- Minimal maintenance requirements.

- Easy operation.

Considerations:

- Limited by the availability of a power source.

- Often less powerful than gas-powered models for heavy-duty tasks.

Single-Direction vs. Reversible Models

- Single-Direction Rammers: Move forward only, making them perfect for straightforward, smaller tasks.

- Reversible Rammers: Can compact soil in both forward and reverse directions, enhancing maneuverability and efficiency in larger or more complex areas.

Operating a Vibratory Rammer Machine Safely

Safety is paramount when using a vibratory rammer. Proper operation not only ensures effective compaction but also prevents injuries and equipment damage.

Liste de contrôle préopératoire

- Inspect the Equipment: Check for any visible damage, leaks, or loose components.

- Fuel and Fluid Levels: Ensure adequate fuel, oil, and hydraulic fluid levels.

- Test the Controls: Verify that the throttle, switches, and other controls function correctly.

Proper Techniques for Use

- Positioning: Stand with a firm grip on the handle and a balanced posture to maintain control.

- Starting the Rammer: Follow the manufacturer’s guidelines for safe startup procedures.

- Operating: Move the rammer slowly over the soil, allowing the machine to compact effectively. Avoid forcing or overusing the machine in a single area.

Post-Operation Care

- Turn off the engine and allow it to cool before cleaning or storing.

- Wipe down the footplate and other components to remove soil or debris.

- Store the rammer in a dry, secure location to prevent rust or damage.

Maintenance and Troubleshooting

Regular maintenance ensures your vibratory rammer performs at its best and has a longer lifespan. Knowing how to address common issues also minimizes downtime during projects.

Routine Maintenance Tasks

- Oil Changes: Replace engine oil at intervals specified in the user manual.

- Air Filter Cleaning: Remove and clean the air filter to maintain proper airflow.

- Inspect the Footplate: Check for signs of wear or damage, as a compromised footplate can reduce compaction efficiency.

- Tighten Bolts: Vibrations can loosen components, so routinely check and tighten bolts.

Common Issues and Fixes

- Engine Won’t Start: Check the fuel level, spark plug, and air filter for blockages.

- Reduced Compaction Force: Inspect the footplate and shock absorbers for wear.

- Excessive Vibration: Ensure all bolts and fasteners are secure, and examine the handle for proper padding.

Environmental Impact of Soil Compaction

While soil compaction is essential for construction and landscaping, it can have unintended environmental consequences if not managed responsibly.

Effects on Soil Health

Compacted soil reduces pore space, limiting water infiltration and root growth. Overcompaction can hinder plant development and lead to erosion due to water runoff.

Pratiques durables

- Use compaction only where necessary, such as structural foundations.

- Incorporate aeration techniques to restore compacted soil in landscaping or agricultural areas.

- Opt for electric vibratory rammers to reduce emissions and noise pollution.

Innovations in Vibratory Rammers

The evolution of vibratory rammers has brought about significant technological advancements, making these tools more efficient, user-friendly, and environmentally sustainable. Manufacturers continually innovate to meet the growing demands of construction and landscaping professionals.

Recent Technological Advancements

- Enhanced Vibration Control: Modern rammers feature advanced shock-absorbing systems that reduce vibrations transmitted to the operator, improving safety and comfort.

- Digital Monitoring Systems: Some models now include digital displays that provide real-time information on operating conditions, such as fuel levels, hours of use, and maintenance alerts.

- Improved Engine Efficiency: Newer engines deliver more power while consuming less fuel and producing fewer emissions, aligning with environmental regulations.

Features Enhancing Usability

- Ergonomic Designs: Adjustable handles and lightweight materials ensure easier handling and reduced fatigue during prolonged use.

- Noise Reduction Technology: Innovations in muffler systems have made vibratory rammers quieter, making them suitable for urban environments.

- Eco-Friendly Options: Electric and hybrid models cater to environmentally conscious users without compromising performance.

These advancements ensure vibratory rammers remain relevant and effective, even as project requirements evolve.

Factors to Consider When Buying a Vibratory Rammer

Choosing the right vibratory rammer involves evaluating specific factors that align with your project needs and budget. Investing in the appropriate equipment ensures efficiency and cost-effectiveness.

Principales considérations

-

Taille et poids :

Lightweight rammers are easier to handle and transport, making them ideal for small-scale tasks. Heavier models provide greater compaction force, suitable for demanding projects. -

Source d'alimentation :

- Gas-Powered: Offers portability and higher power, ideal for outdoor or remote areas.

- Electric: Quieter and more eco-friendly, but requires access to electricity.

-

Intended Application:

Determine whether the rammer will be used for compacting cohesive soils in trenches, granular soils on roadbeds, or both. -

Durability and Build Quality:

Look for models with robust construction and quality materials to withstand harsh working conditions. -

Ease of Maintenance:

Opt for a model with accessible components for routine checks and servicing. -

Budget and Cost:

Balance upfront costs with long-term savings from durability, fuel efficiency, and minimal repairs.

Cost Analysis of Vibratory Rammers

Understanding the cost implications of owning a vibratory rammer helps buyers make informed decisions. While upfront costs are important, long-term considerations often outweigh initial expenses.

Fourchettes de prix

- Entry-Level Models: $1,000–$1,500, suitable for occasional use or small-scale projects.

- Mid-Range Models: $1,500–$2,500, offering a balance of power, durability, and features.

- High-End Models: $2,500 and above, designed for professional use with advanced technologies and superior performance.

Long-Term Cost-Benefit Analysis

- Efficacité énergétique : Modern engines reduce operational costs by consuming less fuel.

- Durability: High-quality rammers last longer, minimizing replacement costs.

- Maintenance Costs: Regular maintenance extends the life of the machine, lowering overall expenditure.

While higher-end models require a larger initial investment, their reliability and efficiency often lead to greater savings over time.

Comparison of Vibratory Rammers with Other Tools

Vibratory rammers stand out from other soil compaction tools due to their unique features and advantages. Understanding these differences ensures you select the right equipment for your needs.

Pilonneurs vibrants et compacteurs à plaque

- Précision : Rammers excel in confined spaces and challenging terrains, while plate compactors are better suited for large, flat areas.

- Profondeur de compactage : Rammers deliver deeper compaction, making them ideal for cohesive soils. Plate compactors focus on surface-level compaction for granular soils.

Vibratory Rammers vs. Rollers

- Size and Mobility: Rammers are compact and portable, whereas rollers are bulky and designed for large-scale projects.

- Use Cases: Rollers are perfect for highways and extensive foundations, while rammers handle smaller, intricate tasks with ease.

Real-World Case Studies

Case Study 1: Trench Compaction for Utility Installation

A construction company faced challenges compacting soil in narrow trenches for utility pipes. By using a vibratory rammer, the team achieved precise compaction without disturbing the surrounding soil. The result was a stable foundation, ensuring the longevity of the utility lines.

Case Study 2: Landscaping Success in Urban Gardens

A landscaping firm used electric vibratory rammers to prepare soil for pathways in a residential garden. The compact design and quiet operation minimized disruption, and the pathways remained stable despite frequent foot traffic.

Conclusion: The Essential Role of Vibratory Rammers in Soil Compaction

Vibratory rammers are indispensable tools for achieving effective soil compaction, particularly in confined and challenging environments. Their ability to compact cohesive soils deeply and precisely ensures stable foundations for a wide range of projects, from construction to landscaping.

Advancements in technology have made vibratory rammers more efficient, ergonomic, and environmentally friendly, further enhancing their value. By understanding their operation, maintenance, and appropriate use cases, professionals can maximize the benefits of these powerful machines.

Whether you’re a construction expert or a DIY enthusiast, investing in the right vibratory rammer can save time, effort, and costs while ensuring the success of your project.

À propos de nous

Wuxi Pinnacle Mechanical Equipment Co, Ltd. (PME) En tant qu'entreprise spécialisée de premier ordre, nous servons des clients du monde entier. PME se spécialise dans la production de compacteurs à plaque, de pilonneuses, de scies à sol et de vibrateurs à béton pour l'industrie mondiale de la construction. Nous produisons également des moteurs, des générateurs et des pompes à eau. Les forces de PME proviennent de notre équipe solide et de nos ressources abondantes.

Nous disposons de lignes de production et d'assemblage complètes pour différentes machines. Une équipe d'ingénieurs en chef, de techniciens supérieurs et d'inspecteurs du contrôle qualité est équipée de divers équipements de finition, d'inspection des pièces détachées et de test des produits, afin de garantir la production et l'innovation. Ainsi, nous pouvons contrôler chaque étape de la production, de l'usinage de finition des pièces détachées à l'assemblage des produits, en passant par la découpe et le soudage des plaques d'acier et la pulvérisation de la peinture. Il en résulte un contrôle efficace de la qualité des produits.

Forte de plus de 20 ans d'expérience en matière d'exportation, PME exporte vers plus de 68 pays et régions, dont l'Amérique du Nord, l'Amérique du Sud, l'Europe, l'Asie du Sud-Est, le Moyen-Orient et l'Afrique. Nous formons également des sociétés stratégiques avec de nombreuses entreprises multinationales.

Salon de l'usine

Laissez notre expertise en matière de compacteurs à plaques sur mesure faire passer vos projets à la vitesse supérieure.

Pourquoi nous choisir ?

Fabricant professionnel de machines de construction avec service OEM

Nous sommes un fabricant de premier plan dans l'industrie des machines de construction, offrant des services de premier ordre en tant que fabricant d'équipement d'origine (OEM). Notre engagement en faveur de l'innovation et de l'ingénierie de précision garantit que nos machines répondent aux besoins spécifiques de nos clients, en fournissant des solutions personnalisées qui améliorent l'efficacité et la performance sur le chantier.

20 ans d'expérience en matière de production et d'exportation

Avec deux décennies d'expérience dans la production et l'exportation, nous nous sommes forgé une solide réputation en fournissant des équipements de construction fiables et de haute qualité dans le monde entier. Nos connaissances approfondies et notre expertise dans l'industrie nous permettent de comprendre les défis uniques des différents marchés, ce qui garantit que nos produits sont adaptés pour répondre aux normes mondiales.

Plus de 20 types d'équipements de chantier sont disponibles pour la sélection

Nous proposons une gamme diversifiée de plus de 20 types d'équipements de chantier, répondant aux différents besoins de l'industrie. Des machines lourdes aux outils spécialisés, notre gamme de produits est conçue pour soutenir chaque phase de la construction, offrant à nos clients la flexibilité de choisir l'équipement approprié pour leurs projets.

10 ans et plus de contrôle de la qualité des produits

Nos processus rigoureux de contrôle de la qualité ont été affinés pendant plus de 10 ans, garantissant que chaque pièce d'équipement que nous produisons répond aux normes les plus élevées. Notre équipe dédiée au contrôle de la qualité surveille méticuleusement chaque étape de la production, garantissant que nos produits offrent des performances et une durabilité constantes sur le terrain.

8+ ans d'expérience des travailleurs qualifiés

Notre équipe est composée de travailleurs hautement qualifiés ayant plus de 8 ans d'expérience dans l'industrie des machines de construction. Leur expertise et leur dévouement se reflètent dans la précision et le savoir-faire de nos produits, garantissant que chaque détail est exécuté à la perfection.

8 ateliers, 12 lignes de production

Avec 8 ateliers ultramodernes et 12 lignes de production, nos capacités de fabrication sont conçues pour répondre efficacement aux demandes à grande échelle. Nos installations de pointe nous permettent de maintenir un processus de production rationalisé, garantissant la livraison en temps voulu de machines de haute qualité à nos clients dans le monde entier.

Une efficacité supérieure dans la construction grâce à nos machines conçues par des experts

Découvrez un monde d'équipements de construction avancés conçus pour répondre aux exigences des chantiers modernes. Avec 20 ans d'expérience dans l'industrie et un engagement de qualité, nos machines sont conçues pour augmenter la productivité et assurer la fiabilité de chaque projet. Explorez notre gamme diversifiée et découvrez la différence des solutions conçues avec précision.