Compacteur à pilon PME-RM65

Si vous êtes à la recherche d'un compacteur à pilon, nous pouvons vous aider à choisir le modèle le plus approprié. pilon de bourrage pour votre entreprise.

Compacteur à pilon PME-RM65

The PME-RM65 Rammer Compactor is a powerful, reliable tool designed for professional contractors tackling demanding soil compaction jobs. Featuring a robust 345 x 285 mm foot and delivering a high tamping force of 13 KN, it reaches a leap height of 85 mm, making it ideal for compacting tough soils in a range of applications.

De puissantes performances

The PME-RM65 is powered by a choice of Honda GX100 or Robin EH09 engines, both known for durability and consistent performance. Its air-cooled, single-cylinder, 4-stroke petrol engine is optimized for efficiency and reliability, supported by a generous 2.8 L fuel tank for extended operation on the job. With a frequency of 680 VPM, the PME-RM65 provides powerful, consistent impact, suitable for compacting cohesive and challenging soil types, making it a go-to solution for even the toughest compaction tasks.

Application polyvalente

Designed for optimal performance in narrow and confined spaces, the PME-RM65 excels in applications requiring precise and powerful compaction, such as foundation preparation and trench work. Its design and impact force make it ideal for cohesive soils like clay and silt, as well as mixed soils, ensuring maximum stability for subgrades and bases. This rammer compactor meets the needs of contractors, rental services, and any professional requiring high-powered, versatile compaction equipment.

Construit pour durer

Durability is at the core of the PME-RM65’s construction. Made from high-quality materials, it is engineered to withstand the demands of rigorous, continuous use on tough job sites. The sturdy build and reliable performance make it perfect for projects like subgrade preparation, trench compaction, and asphalt repair, providing long-lasting value and dependability.

Applications

- Compaction des fondations et des semelles

- Trench Compaction for Utility and Pipeline Installation

- Subgrade and Base Preparation

- Retaining Wall Base Compaction

- Roadway and Pavement Repair Work

- Compaction des sols cohésifs et mixtes (par exemple, argile, limon)

- Soil Stabilization for Landscaping

- Patchwork on Asphalt Surfaces

- Compactage en espace confiné ou étroit

With its superior tamping force, reliable engine, and durable construction, the PME-RM65 Rammer Compactor is engineered for high-performance soil compaction, making it a valuable asset for professional contractors and equipment rental providers alike.

Principales spécifications

| Modèle | Compacteur à pilon PME-RM65 |

|---|---|

| Moteur | Honda GX100 ; Robin EH09 |

| Type de moteur | Moteur à essence 4 temps, monocylindre, refroidi par air |

| Réservoir de carburant [L] | 2.8 |

| Hauteur de saut [mm] | 85 |

| Fréquence [VPM] | 680 |

| Force d'appui [KN] | 13 |

| Taille de la plaque (LxL) [cm] | 345x285 |

| Poids net / poids brut [kg] | 68/78 |

| Emballage (LxLxH) [cm] | 72x38x108 |

AVANTAGE

Réservoir de carburant renforcé

Le réservoir de carburant est fabriqué à partir de matériaux résistants aux chocs et de raccords sûrs, ce qui garantit un stockage fiable du carburant et évite les fuites dans des conditions de travail difficiles.

Moteur robuste

Équipé d'un moteur puissant et fiable de marques renommées, il garantit des performances fluides, un faible niveau sonore, un entretien minimal et une grande efficacité énergétique.

Système avancé d'absorption des chocs

La conception améliorée de l'absorption des chocs réduit considérablement les vibrations dans les mains de l'opérateur, offrant ainsi une expérience d'utilisation confortable et contrôlée.

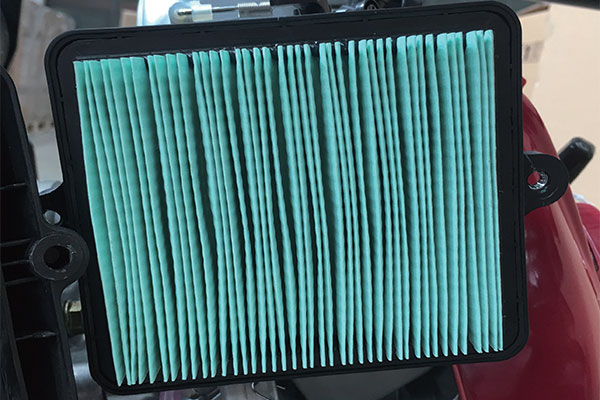

Système efficace de purification de l'air

Un système de filtre à air sophistiqué retient efficacement la poussière et les débris, ce qui permet de garder le moteur plus propre et de réduire les besoins d'entretien pour prolonger la durée de vie des performances.

Soufflet pliant en polyuréthane

Le soufflet en polyuréthane flexible à haute résistance offre une durabilité et une longévité accrues, résistant à la fissuration et à la déformation même en cas d'utilisation intensive.

Plaque de base durable

Une plaque de base renforcée en acier de haute qualité, conçue pour une stabilité maximale et une efficacité de compactage optimale sur différents terrains.

QUESTIONS ET RÉPONSES

Rammer compactors are highly effective on cohesive soils, such as clay and silt, due to their strong impact force, which pushes down and compacts tightly. They can also be used on granular soils, but vibratory compactors might be more efficient for sandy or gravelly terrains.

While gasoline-powered rammers generally offer more power, electric models are catching up with technological improvements. For most light-to-medium-duty tasks, electric compactors can perform comparably to gasoline models, with the added benefit of reduced emissions and noise.

Yes, rammer compactors are often used in small asphalt repair projects where precise compaction is required, such as pothole filling or small pavement patches. However, for larger asphalt areas, a vibratory compacteur à plaque or roller may be more suitable.

Operators should wear PPE, including gloves, safety glasses, and hearing protection. Training in proper operation, keeping a firm grip on handles, and avoiding sharp or unstable ground surfaces are all crucial to safe operation.

If your project involves compacting soil within narrow trenches, such as for pipeline installation, a trench rammer is ideal due to its slim design. Standard rammers are better suited for more open, general-purpose compaction tasks.

Autres produits similaires

Scie à béton PME-Q400

Scie à béton PME-Q350

Scie routière PME-Q300

Rouleau Vibro Ride On PME-R6000

Rouleau compacteur routier PME-R3500

Rouleau de chantier PME-R3000

Plus de 20 ans d'expérience

Fabricant de machines de construction

Fabricant professionnel de petites machines de construction, les principaux produits comprennent le compacteur à plaque, pilon de bourragerouleau compresseur, scie à sol, vibrateur de béton, générateur, etc.

Pilon de bourrage

Les pilonneuses jouent un rôle essentiel dans la construction moderne. Elles sont largement utilisées pour leur efficacité à compacter la terre, le gravier et d'autres matériaux granulaires. Connues pour leur mouvement à fort impact, les pilonneuses stabilisent le sol, fournissant des fondations solides pour les routes, les chemins et les bâtiments. Elles fournissent les surfaces compactées nécessaires à diverses applications de construction. Leur force d'impact puissante et leur polyvalence en font un choix de premier ordre pour les entrepreneurs et les constructeurs, assurant des fondations solides et fiables dans chaque projet.

Rammer Compactors: A Key Tool for Ground Preparation

In construction, quality ground preparation is the backbone of any successful project, and few tools serve this purpose as effectively as rammer compactors. From strengthening soil to ensuring stability for infrastructure, rammer compactors offer the precision and power needed for a variety of ground preparation tasks. This article explores the role of rammer compactors in construction, highlighting their features, applications, benefits, and more.

1. Introduction to Rammer Compactors

Construction sites rely on stability, and a well-compacted ground is critical to achieve that. Rammer compactors play an essential role in compacting soil, sand, gravel, and other materials, creating a solid foundation for further construction activities. Unlike larger compactors, rammers are designed for precise, small-scale compaction tasks, especially in tight or challenging spaces. Their portability and targeted impact make them invaluable for tasks like preparing the ground for pavements, trenches, and small structures.

2. What are Rammer Compactors and How Do They Work?

Rammer compactors are mechanical devices designed to apply intense force onto the ground, reducing air pockets in the soil and increasing its density. They work through a repetitive tamping action, with each strike pushing down to compact the material underneath. This compacting process is crucial for avoiding ground settlement issues, especially in load-bearing structures.

2.1 The Basics of Ground Compaction

Compaction is the process of increasing soil density by expelling air from the void spaces. Properly compacted ground improves stability and load-bearing capacity, reducing the risk of shifting or erosion over time. In applications where precision is required, such as around pipelines and foundations, rammer compactors offer an ideal solution.

2.2 Rammer Compactors: Design and Components

Typically, a rammer compactor consists of a handle, a powerful motor or engine, and a compacting foot. The foot, also known as a plate or shoe, repeatedly strikes the ground with considerable force, driven by the motor. Many models feature ergonomic handles to reduce user fatigue, and some include adjustable settings to control the impact force and frequency.

3. Types de compacteurs à pilon

Rammer compactors come in various models to meet different construction needs. The choice of model often depends on the type of ground to be compacted and the project’s specific requirements.

3.1 Standard Rammers

Standard rammers are versatile tools ideal for compacting granular soils and cohesive materials. These models offer a balance of power and maneuverability, making them suitable for general-purpose applications.

3.2 Vibratory Rammers

Vibratory rammers introduce vibration into the compaction process, enhancing their effectiveness on dense materials like asphalt and clay. The additional vibration helps settle particles more efficiently, achieving a higher degree of compaction.

3.3 Marteaux de tranchée

Designed for use in narrow spaces, trench rammers have a slender footprint, allowing them to fit inside tight trenches and areas where standard rammers may be too bulky. These models are ideal for compacting soil around pipelines and utility installations.

4. Key Features of Rammer Compactors

Rammer compactors come with several distinctive features that enhance their functionality and ease of use. Choosing the right rammer involves understanding how each feature benefits specific tasks.

4.1 Weight and Balance

The weight of a rammer compactor is a critical factor in its performance. Heavier rammers generally deliver a stronger impact, suitable for more compacted soil types, while lighter models are better for areas where delicate handling is required. The balance between weight and handling affects user control and efficiency.

4.2 Power Source Options: Gasoline vs. Electric

Rammer compactors are typically powered by gasoline or electric engines. Gasoline-powered rammers are known for their portability and ability to deliver high power in remote areas. Electric rammers, while generally quieter and cleaner, require a power source and may be more suitable for sites with easy access to electricity.

4.3 Impact Frequency and Force

The impact frequency and force of a rammer determine how effectively it can compact the ground. High-impact models are beneficial for hard soils, while adjustable impact levels can be advantageous in applications where a gentler approach is required.

5. Applications of Rammer Compactors in Construction

Rammer compactors are highly versatile and find applications across a wide range of construction scenarios. Their compact design and powerful impact make them ideal for targeted compaction in areas that larger equipment cannot reach.

5.1 Soil and Sand Compaction

In road construction and landscaping, compacting soil and sand is essential to prevent shifting or erosion. Rammer compactors are frequently used for compacting these materials, especially in smaller or confined spaces.

5.2 Asphalt and Pavement Work

For pavement repairs or new asphalt installations, rammers provide the necessary pressure to bond the asphalt and prevent cracking over time. Their impact and portability make them perfect for patchwork and small areas of asphalt placement.

5.3 Pipeline and Utility Trench Compaction

When laying pipelines or utility lines, compacting the ground around the installation helps prevent settling that could lead to pipe damage. Trench rammers are particularly useful for this purpose, ensuring that the ground around utilities is solid and stable.

6. Advantages of Using Rammer Compactors

Rammer compactors offer several benefits that make them a preferred choice for contractors and construction crews, especially in projects that demand precise ground preparation.

6.1 Amélioration de la stabilité des sols

One of the primary benefits of using a rammer compactor is the increased soil stability it provides. By compressing soil and reducing the void spaces, these compactors create a solid base that resists shifting and settling. This stability is particularly valuable in projects involving structural foundations, ensuring that the ground remains firm and secure for years to come.

6.2 Increased Work Efficiency

Rammer compactors are designed to be efficient, allowing workers to compact soil quickly and with minimal effort. Their powerful impact and targeted design enable faster compaction in small or difficult-to-reach areas, reducing the need for larger, cumbersome equipment. This efficiency not only saves time but also allows for smoother project timelines.

6.3 Cost Savings and Durability

With proper maintenance, rammer compactors are highly durable and can withstand demanding work conditions over long periods. Their robust construction and ability to handle tough jobs mean that companies can save on frequent replacements and repairs. Additionally, the enhanced ground stability they provide helps prevent costly issues like foundation settling, which can lead to expensive repairs in the future.

7. Choosing the Right Rammer Compactor for Your Project

Selecting the right rammer compactor involves considering various factors specific to the needs of the project. The correct choice can make a significant difference in both efficiency and effectiveness.

7.1 Exigences spécifiques au projet

Different projects require different types of compactors. For instance, if the project involves compacting clay or dense soil, a pilon vibrant may be ideal due to its additional vibration capabilities. For pipeline work in narrow trenches, a trench rammer would be a better choice due to its slim design. Evaluating the type of soil, the area size, and any obstacles helps ensure the right rammer is selected.

7.2 Budget and Maintenance Considerations

Budget is another important factor when choosing a rammer compactor. While high-powered models with advanced features might have a higher upfront cost, they can offer long-term savings in terms of durability and reduced maintenance needs. On the other hand, a basic model may be sufficient for occasional or lighter work, offering a budget-friendly option without compromising quality.

8. Maintenance Tips for Rammer Compactors

To keep a rammer compactor running effectively, regular maintenance is essential. Proper upkeep not only extends the life of the machine but also ensures it performs at its best on the job.

8.1 Nettoyage et inspection réguliers

After each use, it’s important to clean the rammer compactor, especially the foot or shoe, which comes into direct contact with the soil. Dirt buildup can affect compaction efficiency and even cause wear on moving parts. Additionally, performing a visual inspection can help spot any loose or damaged components early on, preventing costly repairs.

8.2 Engine and Component Care

For gasoline-powered rammers, regular engine maintenance—such as oil changes, air filter cleaning, and spark plug replacement—is crucial. Battery-operated or electric models also require periodic checks to ensure the power source remains reliable and effective. Lubricating moving parts can also prevent friction-based wear.

8.3 Dépannage des problèmes courants

Common issues with rammer compactors include reduced impact force, engine problems, and component wear. Regular inspections can identify these issues before they escalate. For example, if the rammer is not delivering sufficient impact, checking for clogs in the shoe or foot, as well as ensuring proper engine performance, can often resolve the issue quickly.

9. Safety Precautions When Using Rammer Compactors

Rammer compactors are powerful tools, and safety should always be a priority when operating them. Following established safety guidelines helps protect workers and ensures the equipment is used responsibly.

9.1 Équipement de protection individuelle (EPI)

Operators should always wear appropriate PPE, including gloves, safety goggles, and steel-toed boots, when using a rammer compactor. Hearing protection may also be necessary, especially when working with gasoline-powered models that produce high noise levels.

9.2 Safe Operation Guidelines

Operators must be trained to handle the rammer compactor correctly. Safe operation includes maintaining a stable stance, using the handles for balance, and avoiding sharp movements that could lead to loss of control. Operating the compactor at a steady pace and avoiding uneven surfaces helps ensure consistent compaction and reduces the risk of injury.

9.3 Emergency Procedures

In case of equipment failure or an accident, having an emergency plan in place is essential. This may include shutting off the power source, moving to a safe location, and contacting appropriate personnel for assistance.

10. Environmental Considerations with Rammer Compactors

Modern construction practices increasingly emphasize environmental sustainability, and rammer compactors can support this through energy-efficient models and emissions control features.

10.1 Noise and Emission Control

Gasoline-powered compactors, while powerful, can produce emissions and noise that impact the surrounding environment. Choosing models with noise-reducing technology and low-emission engines can help mitigate these effects, making them suitable for use in residential or environmentally sensitive areas.

10.2 Energy Efficiency and Sustainability

Electric and battery-operated rammer compactors are becoming more popular due to their cleaner operation and reduced carbon footprint. These models are energy-efficient, produce zero emissions during use, and can be a more environmentally friendly choice, especially for projects where sustainability is a key consideration.

11. Popular Brands and Models of Rammer Compactors

The construction industry offers a range of rammer compactor brands, each with its own strengths. Understanding the options can help in selecting a reliable, high-performance model.

11.1 Wacker Neuson Rammer Compactors

Wacker Neuson is known for its durable and high-performing compactors. Their models often feature advanced ergonomics and vibration control, making them a preferred choice for heavy-duty applications.

11.2 Honda-Powered Rammers

Rammers powered by Honda engines are known for reliability and fuel efficiency. These models deliver consistent power and are often favored by contractors for their long-lasting performance and easy maintenance.

11.3 Battery-Operated Models

Battery-operated rammers are gaining popularity due to their environmental benefits and reduced operating noise. These models are particularly useful in urban areas or projects with strict noise restrictions.

12. Innovations in Rammer Compactor Technology

As construction technology advances, so do the tools essential to ground preparation. Recent innovations in rammer compactors focus on efficiency, ease of use, and reducing environmental impact, making these machines even more effective and sustainable.

12.1 Advances in Compaction Efficiency

Manufacturers are continually refining rammer compactors to improve compaction efficiency. Newer models incorporate enhanced impact mechanisms that deliver higher force with each strike, allowing workers to achieve optimal compaction in fewer passes. This increase in efficiency not only speeds up project timelines but also reduces fuel or battery consumption, contributing to cost savings.

12.2 Noise Reduction and Ergonomics

Working with rammer compactors can be physically demanding, especially over extended periods. Innovations in ergonomics, such as vibration-reducing handles and adjustable grip designs, have made operating these machines more comfortable for users, helping to reduce fatigue and strain. Noise reduction features, including insulated engine compartments and quieter motor designs, further enhance the user experience, making rammer compactors suitable for noise-sensitive environments.

12.3 Digital Monitoring Features

Some of the latest rammer compactors come equipped with digital monitoring systems that track operational data like impact force, engine health, and usage duration. This real-time data allows operators to optimize compaction performance and identify maintenance needs before problems arise. Digital tracking can also help companies monitor tool usage, improve efficiency, and ensure safety protocols are followed.

13. Conclusion: The Importance of Rammer Compactors in Construction

Rammer compactors are indispensable tools in the construction industry, contributing significantly to the quality and durability of foundations, pavements, and utility installations. Their ability to provide focused, powerful compaction in tight spaces makes them ideal for projects requiring precision and stability. By investing in a high-quality rammer compactor and following proper maintenance and safety protocols, contractors can ensure their projects stand the test of time.

In the ever-evolving field of construction, rammer compactors remain a staple for efficient ground preparation. As technology advances, these machines continue to become more effective, user-friendly, and environmentally responsible, cementing their status as a key tool for ground preparation in construction.

À propos de nous

Wuxi Pinnacle Mechanical Equipment Co, Ltd. (PME) En tant qu'entreprise spécialisée de premier ordre, nous servons des clients du monde entier. PME se spécialise dans la production de compacteurs à plaque, de pilonneuses, de scies à sol et de vibrateurs à béton pour l'industrie mondiale de la construction. Nous produisons également des moteurs, des générateurs et des pompes à eau. Les forces de PME proviennent de notre équipe solide et de nos ressources abondantes.

Nous disposons de lignes de production et d'assemblage complètes pour différentes machines. Une équipe d'ingénieurs en chef, de techniciens supérieurs et d'inspecteurs du contrôle qualité est équipée de divers équipements de finition, d'inspection des pièces détachées et de test des produits, afin de garantir la production et l'innovation. Ainsi, nous pouvons contrôler chaque étape de la production, de l'usinage de finition des pièces détachées à l'assemblage des produits, en passant par la découpe et le soudage des plaques d'acier et la pulvérisation de la peinture. Il en résulte un contrôle efficace de la qualité des produits.

Forte de plus de 20 ans d'expérience en matière d'exportation, PME exporte vers plus de 68 pays et régions, dont l'Amérique du Nord, l'Amérique du Sud, l'Europe, l'Asie du Sud-Est, le Moyen-Orient et l'Afrique. Nous formons également des sociétés stratégiques avec de nombreuses entreprises multinationales.

Salon de l'usine

Laissez notre expertise en matière de compacteurs à plaques sur mesure faire passer vos projets à la vitesse supérieure.

Pourquoi nous choisir ?

Fabricant professionnel de machines de construction avec service OEM

Nous sommes un fabricant de premier plan dans l'industrie des machines de construction, offrant des services de premier ordre en tant que fabricant d'équipement d'origine (OEM). Notre engagement en faveur de l'innovation et de l'ingénierie de précision garantit que nos machines répondent aux besoins spécifiques de nos clients, en fournissant des solutions personnalisées qui améliorent l'efficacité et la performance sur le chantier.

20 ans d'expérience en matière de production et d'exportation

Avec deux décennies d'expérience dans la production et l'exportation, nous nous sommes forgé une solide réputation en fournissant des équipements de construction fiables et de haute qualité dans le monde entier. Nos connaissances approfondies et notre expertise dans l'industrie nous permettent de comprendre les défis uniques des différents marchés, ce qui garantit que nos produits sont adaptés pour répondre aux normes mondiales.

Plus de 20 types d'équipements de chantier sont disponibles pour la sélection

Nous proposons une gamme diversifiée de plus de 20 types d'équipements de chantier, répondant aux différents besoins de l'industrie. Des machines lourdes aux outils spécialisés, notre gamme de produits est conçue pour soutenir chaque phase de la construction, offrant à nos clients la flexibilité de choisir l'équipement approprié pour leurs projets.

10 ans et plus de contrôle de la qualité des produits

Nos processus rigoureux de contrôle de la qualité ont été affinés pendant plus de 10 ans, garantissant que chaque pièce d'équipement que nous produisons répond aux normes les plus élevées. Notre équipe dédiée au contrôle de la qualité surveille méticuleusement chaque étape de la production, garantissant que nos produits offrent des performances et une durabilité constantes sur le terrain.

8+ ans d'expérience des travailleurs qualifiés

Notre équipe est composée de travailleurs hautement qualifiés ayant plus de 8 ans d'expérience dans l'industrie des machines de construction. Leur expertise et leur dévouement se reflètent dans la précision et le savoir-faire de nos produits, garantissant que chaque détail est exécuté à la perfection.

8 ateliers, 12 lignes de production

Avec 8 ateliers ultramodernes et 12 lignes de production, nos capacités de fabrication sont conçues pour répondre efficacement aux demandes à grande échelle. Nos installations de pointe nous permettent de maintenir un processus de production rationalisé, garantissant la livraison en temps voulu de machines de haute qualité à nos clients dans le monde entier.

Une efficacité supérieure dans la construction grâce à nos machines conçues par des experts

Découvrez un monde d'équipements de construction avancés conçus pour répondre aux exigences des chantiers modernes. Avec 20 ans d'expérience dans l'industrie et un engagement de qualité, nos machines sont conçues pour augmenter la productivité et assurer la fiabilité de chaque projet. Explorez notre gamme diversifiée et découvrez la différence des solutions conçues avec précision.