Rodillo compactador de suelos PME-R2000

When you are looking for a soil compactor roller, we can assist you in selecting the most suitable rodillo compactador para su negocio.

Rodillo compactador de suelos PME-R2000

The PME-R2000 Soil Rodillo compactador is a high-capacity machine designed for heavy-duty construction and soil stabilization projects. With its dual rollers measuring 610 mm in diameter and 1000 mm in width, this roller delivers unmatched performance and efficiency, making it ideal for large-scale infrastructure, roadwork, and foundation preparation tasks.

Potente rendimiento

Equipped with the robust ChangChai ZN390B engine, the PME-R2000 provides dependable power and consistent operation for even the most demanding jobs. Its hydraulic double-wheels drive system ensures smooth and precise handling, while the hydraulic front-wheel vibration system delivers a powerful centrifugal force of 30 KN at a vibration frequency of 75 Hz. The 0.5 mm nominal amplitude allows for deep and uniform compaction, ensuring a stable and durable foundation across various soil and material types.

Aplicación versátil

The PME-R2000 is engineered for versatility, excelling in a wide range of applications from road construction to soil stabilization and subgrade preparation. Its hydraulic steering system offers a steering radius of 2300 mm, enabling exceptional maneuverability even in confined spaces. With a gradeability of 30°, it performs effectively on steep slopes and uneven terrain. The impressive travel speed range of 0-12 km/h ensures efficient progress across large job sites, saving time without compromising precision.

Construido para durar

Built for durability, the PME-R2000 is constructed from high-grade materials to withstand the rigors of continuous use in challenging environments. Its advanced hydraulic systems guarantee reliable operation and reduced maintenance, minimizing downtime and maximizing productivity. Whether compacting subgrades, stabilizing soils, or working on large infrastructure projects, the PME-R2000 is designed to provide consistent, high-quality results.

Aplicaciones

- Construcción y mantenimiento de carreteras

- Soil Stabilization and Subgrade Preparation

- Foundation and Structural Work

- Large-Scale Infrastructure Development

- Compacting on Slopes and Uneven Terrain (Gradeability: 30°)

- High-Efficiency Compaction for Large Job Sites

- Pathways, Driveways, and Landscaping

- Tight and Open Workspaces

With its powerful engine, advanced hydraulic systems, and efficient design, the PME-R2000 Compactador de tierra Roller is the ultimate choice for contractors and professionals. Its reliability, robust performance, and user-friendly operation make it an indispensable tool for achieving superior compaction results in even the most demanding conditions.

Especificaciones

| Modelo | Rodillo compactador de suelos PME-R2000 |

|---|---|

| Motor | ChangChai ZN390B |

| Roller size [diameter x width] | 2xφ610x1000 mm |

| Drive type | Hydraulic double wheels drive |

| Vibration type | Hydraulic front wheel vibrate |

| Steering mode | Hydraulic control |

| Steering radius | 2300 mm |

| Nominal amplitude | 0.5 mm |

| Frecuencia de vibración | 75 Hz |

| Centrifugal force | 30 KN |

| Gradeability | 30° |

| Travel speed | 0-12 km/h |

| N.W./G.W. | 1980/2000 kg |

| Package size | 250x120x175 cm |

VENTAJA

Exquisite Workmanship

The hood of the apisonadora showcases excellent craftsmanship. The bright yellow paint is flawlessly applied, providing a smooth and vibrant finish.

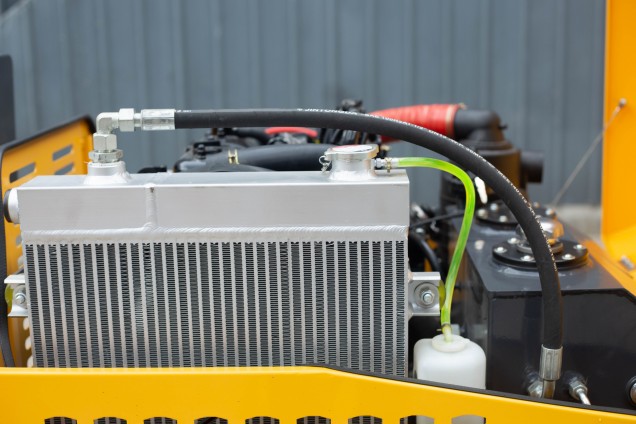

Efficient Engine Compartment Organization

The engine compartment is organized with components such as hoses, filters, and the engine block properly placed.This organized layout facilitates maintenance and ensures the smooth operation of the road roller's engine.

Large Compaction Drum

The roller features a large compaction drum at the front. This drum is responsible for compacting soil, asphalt, and other construction materials. The large size of the drum ensures a smooth and even compaction surface.

Intuitive Control Panel Layout

The control panel features a well - arranged layout with clearly marked buttons and gauges. This design allows for easy access and operation, reducing the likelihood of errors and improving the efficiency of the road roller's functions.

Comfortable Seat

The roller is equipped with a cushioned seat, providing comfort for the operator during extended use. It is flanked by handlebars, providing a secure and comfortable operating position for the operator, which enhances the overall usability of the road roller.

Drum with Scraper

The roller is equipped with a drum that has a built - in scraper. The scraper helps to remove any material that may stick to the drum during the compaction process, ensuring that the drum remains clean and effective. This feature is crucial for maintaining the quality of the compaction work.

PREGUNTAS Y RESPUESTAS

The main types include smooth-wheel rollers, padfoot rollers, pneumatic rollers, and vibratory rollers, each suited for different soil types and applications.

Yes, but the type of compactor roller should match the soil type. For example, smooth-wheel rollers work best on granular soils, while padfoot rollers are ideal for cohesive soils.

Proper moisture content allows soil particles to compact efficiently. Too little or too much moisture reduces compaction effectiveness.

Vibratory rollers are generally more effective for deep and cohesive soil compaction, while static rollers work well for surface-level compaction.

With proper maintenance, a soil compactor roller can last 10-15 years or more, depending on usage and care.

Prices range from $15,000 to over $100,000, depending on the type and features.

Yes, mini rollers are available for landscaping and small-scale construction.

Assess your soil type, project size, and budget to make an informed decision.

Always wear protective gear, follow the manufacturer’s guidelines, and ensure proper training for operators.

Otros productos similares

Sierra para cortar hormigón PME-Q400

Sierra de hormigón PME-Q350

Sierra de carretera PME-Q300

Rodillo vibratorio PME-R6000

Rodillo compactador PME-R3500

Rodillo compactador para la construcción PME-R3000

Más de 20 años de experiencia

Fabricante de maquinaria de construcción

Fabricante profesional de pequeña maquinaria de construcción, los principales productos incluyen compactador de placas, apisonadorapisonadora, sierra de piso, vibrador de hormigóngenerador, etc.

Rodillo compactador de tierra

A soil compactor roller is a heavy-duty construction machine designed to compress soil, asphalt, or gravel. It’s an essential tool for ensuring a stable and durable foundation for roads, buildings, and other structures.

The Ultimate Guide to Soil Compactor Rollers

Introducción a los rodillos compactadores de tierra

What Are Soil Compactor Rollers?

Soil compactor rollers are essential machinery used in construction and engineering projects to compact soil, gravel, or asphalt. By reducing the voids between soil particles, these rollers ensure a stable and durable base for structures and roads.

Importance of Soil Compaction in Construction

Proper soil compaction minimizes settlement, prevents water seepage, and enhances load-bearing capacity. This process is crucial for the longevity of construction projects, including highways, bridges, and foundations.

How Soil Compactor Rollers Work

Key Components of a Soil Compactor Roller

A soil compactor roller typically consists of:

Drum or Rollers: The primary compaction component.

Engine: Powers the machine.

Vibration Mechanism: Enhances compaction efficiency.

Operator Cabin or Controls: For maneuvering and operation.

The Mechanics of Soil Compaction

Soil compaction involves applying force to soil particles, reducing air voids, and increasing density. Soil compactor rollers achieve this through two main mechanisms: static pressure and vibration.

Static vs. Vibratory Compaction

Static compaction relies on the roller’s weight to compress the soil. It’s best for initial passes over loose material. On the other hand, vibratory compaction uses oscillations to rearrange soil particles, ensuring deeper and more effective compaction, particularly for cohesive soils.

Factores que influyen en la eficacia de la compactación

Tipo de suelo

The type of soil significantly impacts the roller’s efficiency. Granular soils like sand and gravel compact easily with smooth-wheel or vibratory rollers, while cohesive soils require padfoot rollers to achieve proper density.

Contenido de humedad

Soil moisture plays a critical role in compaction. If the soil is too dry, it resists compaction, and if it’s too wet, it becomes unstable. Finding the optimal moisture level, often referred to as the “optimum moisture content,” ensures maximum compaction efficiency.

Tipos de rodillos compactadores de tierra

Rodillos de tambor lisos

Ideal for granular soils like sand and gravel, smooth drum rollers provide even compaction and are widely used in road construction.

Rodillos Padfoot

Designed for cohesive soils like clay, padfoot rollers have studs or “feet” on their drums that knead the soil, ensuring better compaction.

Rodillos neumáticos

These rollers use rubber tires to provide uniform pressure across the soil surface. They’re perfect for asphalt compaction and road maintenance.

Rodillos vibratorios

Combining static weight and vibration, these rollers are versatile and effective for various soil types.

Advantages of Using Soil Compactor Rollers

Increased Load-Bearing Capacity

Compacted soil can support heavier loads, making it ideal for highways and multi-story buildings.

Reducción de la erosión del suelo

By stabilizing the soil, compaction minimizes erosion caused by wind or water.

Aplicaciones de los rodillos compactadores de tierra

Construcción de carreteras

One of the primary uses of soil compactor rollers is in road construction. By compacting the subbase and base layers, they ensure the road can withstand heavy traffic without deforming or cracking.

Foundations and Embankments

Compactor rollers are indispensable in preparing foundations for buildings, bridges, and embankments. Proper compaction provides the stability required to support heavy structures and prevents settlement over time.

Cómo elegir el rodillo compactador de tierra adecuado

Factores a tener en cuenta

Requisitos del proyecto

The type of roller you need depends on the project. For large-scale road construction, vibratory rollers are often preferred for their speed and efficiency. For smaller projects, a smooth-wheel or padfoot roller may suffice.

Coste y presupuesto

Budget constraints also play a role in the decision-making process. While advanced rollers with GPS systems may cost more upfront, their efficiency can lead to long-term savings through reduced operational costs and fewer passes.

Maintenance and Care for Soil Compactor Rollers

Regular Inspection Tips

Routine inspections are essential to keep your compactor roller in top condition. Check the drum or tires for wear, ensure hydraulic systems are functioning properly, and inspect for oil leaks or unusual noises.

Common Maintenance Practices

Maintenance includes cleaning the roller after each use, changing hydraulic fluids as recommended, and lubricating moving parts to prevent wear. Regular servicing by professionals ensures the roller operates efficiently and prolongs its lifespan.

Conclusión

Soil compactor rollers are indispensable in construction, playing a vital role in creating stable foundations for roads, buildings, and other structures. From the various types available to the advanced features of modern models, choosing the right compactor roller can make or break a project’s success. By understanding their mechanics, applications, and maintenance needs, you can ensure efficient operations and long-lasting results.

Quiénes somos

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) Como empresa especializada de primera clase, servimos a clientes de todo el mundo. PME se especializa en la producción de compactador de placa, apisonador, sierra de piso, vibrador de concreto para la industria de la construcción mundial. También producimos motores, generadores y bombas de agua. Los puntos fuertes de PME se basan en nuestro fuerte equipo y ricos recursos.

Disponemos de líneas completas de producción y montaje para diferentes máquinas. Contamos con un equipo de ingenieros jefe, técnicos superiores e inspectores de control de calidad, equipados con diversos equipos de acabado, inspección de piezas de repuesto y pruebas de productos, para salvaguardar la producción y la innovación. Así, podemos controlar cada paso de la producción, desde el mecanizado de acabado de las piezas de repuesto, el corte y la soldadura de la chapa de acero, la pulverización de pintura, hasta el montaje del producto. El resultado es un control eficaz de la calidad del producto.

Con más de 20 años de experiencia exportadora, PME ha exportado a más de 68 países y regiones, incluyendo Norteamérica, Sudamérica, Europa, Sudeste Asiático, Oriente Medio y África. También formamos corporaciones estratégicas con muchas empresas multinacionales.

Fábrica

Deje que nuestra experiencia en Compactadores de Placas Forward personalizados lleve sus proyectos al siguiente nivel.

Por qué elegirnos

Fabricante profesional de maquinaria de construcción con servicio OEM

Somos un fabricante líder en el sector de la maquinaria de construcción y ofrecemos servicios de fabricante de equipos originales (OEM) de primera categoría. Nuestro compromiso con la innovación y la ingeniería de precisión garantiza que nuestra maquinaria satisfaga las necesidades específicas de nuestros clientes, proporcionando soluciones personalizadas que mejoran la eficiencia y el rendimiento en el lugar de trabajo.

20 años de experiencia en producción y exportación

Con dos décadas de experiencia en producción y exportación, nos hemos forjado una sólida reputación por suministrar equipos de construcción fiables y de alta calidad en todo el mundo. Nuestros amplios conocimientos y experiencia en el sector nos permiten comprender los retos específicos de los distintos mercados, garantizando que nuestros productos se adaptan para cumplir las normas mundiales.

Más de 20 tipos de equipos de construcción disponibles para su selección

Ofrecemos una variada gama de más de 20 tipos de equipos para obras de construcción, que satisfacen las distintas necesidades del sector. Desde maquinaria pesada hasta herramientas especializadas, nuestra gama de productos está diseñada para apoyar cada fase de la construcción, proporcionando a nuestros clientes la flexibilidad de elegir el equipo adecuado para sus proyectos.

Más de 10 años controlando la calidad de los productos

Nuestros rigurosos procesos de control de calidad se han perfeccionado a lo largo de más de 10 años, garantizando que cada equipo que producimos cumpla los estándares más exigentes. Nuestro equipo de control de calidad supervisa meticulosamente cada fase de la producción, garantizando que nuestros productos ofrezcan un rendimiento y una durabilidad constantes sobre el terreno.

Trabajadores cualificados con más de 8 años de experiencia

Nuestro equipo está formado por trabajadores altamente cualificados con más de 8 años de experiencia en el sector de la maquinaria de construcción. Su experiencia y dedicación se reflejan en la precisión y artesanía de nuestros productos, garantizando que cada detalle se ejecute a la perfección.

8 talleres, 12 líneas de producción

Con 8 talleres de última generación y 12 líneas de producción, nuestras capacidades de fabricación están diseñadas para satisfacer eficientemente demandas a gran escala. Nuestras avanzadas instalaciones nos permiten mantener un proceso de producción racionalizado, garantizando la entrega puntual de maquinaria de alta calidad a nuestros clientes de todo el mundo.

Consiga una mayor eficacia en la construcción con nuestra maquinaria diseñada por expertos

Descubra un mundo de avanzados equipos de construcción diseñados para satisfacer las exigencias de las obras modernas. Con 20 años de experiencia en el sector y un compromiso con la calidad, nuestra maquinaria está diseñada para aumentar la productividad y garantizar la fiabilidad en cada proyecto. Explore nuestra variada gama y experimente la diferencia de las soluciones diseñadas con precisión.