Tamper Rammer PME-RM85

When you are looking for a tamper rammer, we can assist you in selecting the most suitable apisonador para su negocio.

The PME-RM85 Tamper Rammer is a high-performance machine designed for heavy-duty soil compaction tasks. With a robust 345 x 285 mm plate and a powerful tamping force of 15 KN, it achieves a leap height of 80 mm, making it ideal for compacting dense and cohesive soils across various construction projects.

Potente rendimiento

Powered by a choice of Honda, Robin, Loncin, or diesel engines, the PME-RM85 provides exceptional reliability and versatility. Its air-cooled, single-cylinder, 4-stroke engine is paired with a 3 L fuel tank, ensuring extended operation times and consistent power output. Operating at a frequency of 680 VPM, this tamper rammer delivers robust and reliable compaction, making it suitable for demanding applications on construction sites.

Aplicación versátil

The PME-RM85 is engineered for precision and power, excelling in confined spaces and challenging conditions. Its strong tamping force and moderate leap height make it perfect for compacting cohesive soils such as clay and silt, as well as mixed soil types. Whether you are preparing foundations, compacting trenches, or stabilizing subgrades, this tamper rammer ensures exceptional results for professional contractors and rental services.

Construido para durar

Built with durability in mind, the PME-RM85 features high-quality materials designed to endure continuous use in tough working environments. Its sturdy construction ensures reliable performance for projects such as subgrade preparation, pipeline bedding, and landscaping. This rammer is built to deliver consistent results while standing up to the rigors of daily use.

Aplicaciones

- Trench and Pipeline Compaction

- Preparación de cimientos y zapatas

- Subgrade and Base Layer Compaction

- Retaining Wall Bases

- Road and Asphalt Repair Work

- Compactación de suelos cohesivos y mixtos (por ejemplo, arcilla, limo)

- Soil Stabilization for Construction and Landscaping

- Confined or Narrow Space Compaction

With its exceptional tamping force, versatile engine options, and durable construction, the PME-RM85 Tamper Rammer is a reliable solution for all soil compaction needs. It’s an indispensable tool for construction professionals and rental providers, offering unmatched performance and efficiency.

Especificaciones

| Modelo | Tamper Rammer PME-RM85 |

|---|---|

| Motor | Honda / Robin / Loncin / Motor diesel |

| Tipo de motor | Motor de gasolina / diesel de 4 tiempos, monocilíndrico, refrigerado por aire |

| Depósito de combustible [L] | 3 |

| Altura de salto [mm] | 80 |

| Frecuencia [VPM] | 680 |

| Fuerza de apisonamiento [KN] | 15 |

| Tamaño de la placa (LxA) [cm] | 345x285 |

| N.W./G.W. [kg] | 83/93 |

| Paquete (LxAnxAl) [cm] | 79x44x115 |

VENTAJA

Depósito de combustible reforzado

El depósito de combustible está fabricado con materiales resistentes a los impactos y accesorios seguros, lo que garantiza un almacenamiento fiable del combustible y evita las fugas en condiciones de trabajo exigentes.

Motor robusto

Equipada con un potente y fiable motor de marcas de renombre, que garantiza un rendimiento suave con bajo nivel de ruido, mantenimiento mínimo y eficiencia de combustible.

Sistema avanzado de absorción de impactos

El diseño amortiguador mejorado reduce significativamente las vibraciones en las manos del operador, proporcionando una experiencia de manejo cómoda y controlada.

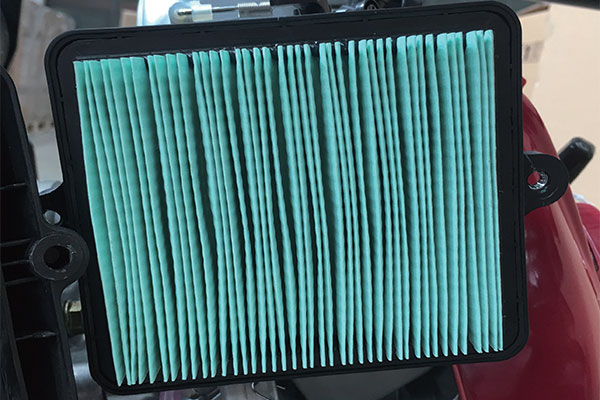

Sistema eficaz de purificación del aire

Un sofisticado sistema de filtro de aire atrapa eficazmente el polvo y los residuos, manteniendo el motor más limpio y reduciendo las necesidades de mantenimiento para prolongar la vida útil del rendimiento.

Fuelle plegable de poliuretano

El fuelle de poliuretano flexible de alta resistencia ofrece una mayor durabilidad y longevidad, resistiendo el agrietamiento y la deformación incluso en condiciones de uso intensivo.

Placa base duradera

Una placa base reforzada construida con acero de alta calidad, diseñada para ofrecer la máxima estabilidad y una eficacia de compactación óptima en diversos terrenos.

PREGUNTAS Y RESPUESTAS

A tamper rammer is used to compact soil, gravel, and other materials, creating a solid base for construction projects.

Tamper rammers use rapid, repetitive force generated by their engine and a piston mechanism to compact soil deeply and evenly.

While tamper rammers excel on cohesive soils, they may require specific configurations for loose or granular materials.

While both are used for compaction, tamper rammers are ideal for small, confined spaces and tougher soils, whereas plate compactors work better on larger, flat areas.

Durability, performance, operator comfort, and advanced safety features distinguish quality models from mediocre ones.

With proper care, a high-quality tamper rammer can last upwards of 10 years, making it a worthwhile investment.

Regular maintenance is key. Check the engine, replace filters, and inspect parts after every 50-100 hours of operation or as specified by the manufacturer.

Yes, many modern models feature fuel-efficient engines and low emissions, making them more environmentally friendly.

Always wear protective gear, ensure proper footing, and follow the manufacturer’s guidelines to prevent accidents.

Otros productos similares

Sierra para cortar hormigón PME-Q400

Sierra de hormigón PME-Q350

Sierra de carretera PME-Q300

Rodillo vibratorio PME-R6000

Rodillo compactador PME-R3500

Rodillo compactador para la construcción PME-R3000

Más de 20 años de experiencia

Fabricante de maquinaria de construcción

Fabricante profesional de pequeña maquinaria de construcción, los productos principales incluyen compactador de placa, apisonadorapisonadora, sierra de piso, vibrador de hormigóngenerador, etc.

Apisonador

Los apisonadores desempeñan un papel vital en la construcción moderna, y se utilizan ampliamente por su eficacia en la compactación de tierra, grava y otros materiales granulares. Conocidos por su movimiento de alto impacto, los apisonadores estabilizan el suelo, proporcionando fuertes cimientos para carreteras, caminos y edificios, así como las superficies compactadas necesarias para diversas aplicaciones de construcción. Su potente fuerza de impacto y su versatilidad los convierten en la mejor elección tanto para contratistas como para constructores, garantizando unos cimientos fuertes y fiables en cada proyecto.

What Are the Key Features of a Good Tamper Rammer?

Introduction to Tamper Rammers

What is a Tamper Rammer?

A tamper rammer, sometimes referred to as a jumping jack, is a high-impact compaction tool specifically engineered to create solid and stable surfaces. It is a must-have for construction workers and landscapers aiming to lay the groundwork for buildings, roads, and pavements. Unlike other compaction equipment like vibratory plates, tamper rammers exert a focused force that penetrates deeper, making them perfect for cohesive soils like clay or silt.

Importance of Choosing the Right Tamper Rammer

The significance of a quality tamper rammer lies in its ability to save time and effort while delivering exceptional results. Poor equipment can lead to uneven surfaces, structural instability, and even safety hazards. With the right machine, users can ensure precision, reliability, and an overall smoother workflow.

Calidad de diseño y construcción

Robust Frame Construction

The frame serves as the skeleton of the tamper rammer, and its durability determines the machine’s lifespan. Premium models use materials like industrial-grade steel or aluminum to resist the wear and tear of daily use. The frame should be corrosion-resistant to withstand challenging environments, including construction sites exposed to water or chemicals.

Ergonomic Design for Operator Comfort

Prolonged use of a tamper rammer can cause operator fatigue, especially if ergonomics are neglected. Modern designs incorporate vibration-dampening technology, padded grips, and balanced weight distribution. These features not only enhance comfort but also prevent long-term physical strain, such as hand-arm vibration syndrome (HAVS).

Power and Performance Features

Engine Specifications and Efficiency

A tamper rammer’s engine must be powerful enough to deliver consistent performance. High-end models often feature 4-stroke engines, which are quieter and more fuel-efficient than their 2-stroke counterparts. The choice of fuel type—gasoline, diesel, or electric—also impacts performance and usability, with electric models gaining popularity for their eco-friendliness.

Impact Force and Compaction Depth

The impact force, typically measured in kilonewtons (kN), indicates the tamper’s ability to compact the soil. Machines with adjustable impact force settings allow users to tailor performance to specific soil conditions. The compaction depth, often ranging from 20 to 30 cm, ensures a stable foundation for heavy-duty applications.

Fuel Efficiency and Runtime

Longer runtimes reduce downtime, enabling operators to complete tasks more efficiently. Fuel-efficient engines not only save money but also minimize environmental impact, a growing concern in the construction industry.

Facilidad de manejo

User-Friendly Controls

Intuitive controls simplify the learning curve for new operators. Features like throttle levers, start-stop buttons, and accessible fuel indicators make the machine easier to operate, even for novices.

Maneuverability in Confined Spaces

Compact tamper rammers are ideal for projects requiring precision in narrow or awkward spaces, such as trenching or pipe installations. A lightweight yet sturdy build further enhances maneuverability.

Durabilidad y mantenimiento

Wear-Resistant Materials

High-wear components like the foot pad, often made of high-carbon steel or polyurethane, are engineered to endure repetitive impacts. This longevity reduces the frequency of replacements, ensuring consistent performance.

Simplified Maintenance and Serviceability

Good tamper rammers feature accessible service points for tasks like oil changes, air filter replacements, and spark plug inspections. Many manufacturers include detailed user manuals and even onboard diagnostic systems to guide maintenance.

Características de seguridad

Anti-Vibration Systems

Excessive vibration can lead to operator fatigue and injuries. Advanced anti-vibration systems, such as shock-absorbing mounts and padded grips, reduce these risks significantly, allowing for longer operational hours.

Safety Shutdown Mechanisms

Automatic shutdown features, triggered by overheating or low oil levels, protect both the machine and the operator from potential hazards.

Key Features of a Good Tamper Rammer

Durabilidad y calidad de construcción

One of the first things to look for in a tamper rammer is its durability. Machines built with high-quality materials like reinforced steel frames and wear-resistant components are designed to withstand harsh job site conditions. A durable tamper rammer won’t just survive the elements; it will also handle constant vibration and impact without breaking down.

Engine Performance

The engine is the heart of any tamper rammer. A good machine features an engine with adequate power output to deliver consistent performance, even on challenging terrains. Additionally, fuel-efficient engines can save you money and reduce environmental impact. Brands offering modern engines with low emissions are an added bonus.

Facilidad de manejo

Who wants to wrestle with a machine that feels like it has a mind of its own? User-friendly controls, ergonomic handles, and excellent maneuverability make a tamper rammer easier to operate. Look for models with intuitive control panels and designs that minimize physical effort for the operator.

Eficacia de compactación

The primary purpose of a tamper rammer is compaction, so its efficiency in this area is critical. Factors like the plate size, impact force, and the ability to work effectively on uneven surfaces determine how well it performs. High compaction power means fewer passes are needed, saving time and energy.

Shock Absorption System

Continuous vibration during operation can lead to operator fatigue and even injuries. A good tamper rammer includes a shock absorption system that minimizes vibrations transmitted to the user. This not only protects the operator but also extends the lifespan of the machine by reducing wear and tear.

Portabilidad

Portability might not seem like a big deal until you’re faced with moving a heavy machine across a worksite. Lightweight and compact designs make tamper rammers easier to transport and store. Some models even come with built-in wheels or handles for added convenience.

Additional Features That Enhance Performance

Adjustable Handle Height

An adjustable handle allows operators of different heights to use the machine comfortably, making it more ergonomic.

Low Vibration Technology

Advanced models incorporate low vibration technology to ensure a smoother and more comfortable experience for the operator.

Noise Reduction Systems

Construction sites are noisy enough. Machines with noise-dampening features are a blessing for both workers and the surrounding environment.

Características de seguridad

Safety features like emergency shut-off switches and protective covers are must-haves. They minimize risks and make operation safer for everyone involved.

Benefits of Investing in a Quality Tamper Rammer

A good tamper rammer isn’t just a tool—it’s an investment. Durable and efficient models last longer, perform better, and require less maintenance. They can significantly improve project timelines, reduce costs, and deliver superior results.

How to Choose the Best Tamper Rammer

Evaluación de las necesidades de su proyecto

Different projects require different levels of compaction. Understand your requirements before making a purchase.

Consideraciones presupuestarias

While quality is key, it’s also important to find a machine that fits your budget. Compare features and prices to get the best value.

Reputación de marca y críticas

Stick to brands known for reliability. Customer reviews and expert recommendations can provide insights into a machine’s real-world performance.

Use Cases and Applications

Construction and Roadwork

Tamper rammers are indispensable for compacting sub-base layers in road construction. Their deep compaction ensures a stable foundation capable of supporting heavy traffic loads.

Landscaping and Foundation Work

In landscaping, these machines help create leveled surfaces for pathways, patios, and retaining walls. They are also crucial for preparing the foundation of structures, ensuring long-term stability.

Economic Value and Cost Efficiency

Initial Investment vs. Long-Term Value

While the upfront cost of a high-quality tamper rammer might seem steep, its durability and performance pay off in the long run. Cheap alternatives often require frequent repairs or replacements, making them more expensive over time.

Resale Value of Quality Tamper Rammers

Well-maintained equipment retains its value, offering a high resale price when it’s time to upgrade.

Consideraciones medioambientales

Emissions Compliance

Many modern tamper rammers meet stringent emissions standards, such as EPA or EU Stage V certifications. These eco-friendly machines reduce pollutants, aligning with global sustainability goals.

Noise Levels and Neighborhood Impact

For projects in residential areas, low-noise models minimize disturbances, ensuring compliance with local noise ordinances and maintaining good relations with neighbors.

Conclusion and Key Takeaways

A good tamper rammer combines durability, efficiency, safety, and operator comfort to deliver exceptional performance across a variety of applications. Whether you’re preparing a foundation for construction or compacting soil for landscaping, investing in a quality model ensures long-lasting results and peace of mind.

Quiénes somos

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) Como empresa especializada de primera clase, servimos a clientes de todo el mundo. PME se especializa en la producción de compactador de placa, apisonador, sierra de piso, vibrador de concreto para la industria de la construcción mundial. También producimos motores, generadores y bombas de agua. Los puntos fuertes de PME se basan en nuestro fuerte equipo y ricos recursos.

Disponemos de líneas completas de producción y montaje para diferentes máquinas. Contamos con un equipo de ingenieros jefe, técnicos superiores e inspectores de control de calidad, equipados con diversos equipos de acabado, inspección de piezas de repuesto y pruebas de productos, para salvaguardar la producción y la innovación. Así, podemos controlar cada paso de la producción, desde el mecanizado de acabado de las piezas de repuesto, el corte y la soldadura de la chapa de acero, la pulverización de pintura, hasta el montaje del producto. El resultado es un control eficaz de la calidad del producto.

Con más de 20 años de experiencia exportadora, PME ha exportado a más de 68 países y regiones, incluyendo Norteamérica, Sudamérica, Europa, Sudeste Asiático, Oriente Medio y África. También formamos corporaciones estratégicas con muchas empresas multinacionales.

Fábrica

Deje que nuestra experiencia en Compactadores de Placas Forward personalizados lleve sus proyectos al siguiente nivel.

Por qué elegirnos

Fabricante profesional de maquinaria de construcción con servicio OEM

Somos un fabricante líder en el sector de la maquinaria de construcción y ofrecemos servicios de fabricante de equipos originales (OEM) de primera categoría. Nuestro compromiso con la innovación y la ingeniería de precisión garantiza que nuestra maquinaria satisfaga las necesidades específicas de nuestros clientes, proporcionando soluciones personalizadas que mejoran la eficiencia y el rendimiento en el lugar de trabajo.

20 años de experiencia en producción y exportación

Con dos décadas de experiencia en producción y exportación, nos hemos forjado una sólida reputación por suministrar equipos de construcción fiables y de alta calidad en todo el mundo. Nuestros amplios conocimientos y experiencia en el sector nos permiten comprender los retos específicos de los distintos mercados, garantizando que nuestros productos se adaptan para cumplir las normas mundiales.

Más de 20 tipos de equipos de construcción disponibles para su selección

Ofrecemos una variada gama de más de 20 tipos de equipos para obras de construcción, que satisfacen las distintas necesidades del sector. Desde maquinaria pesada hasta herramientas especializadas, nuestra gama de productos está diseñada para apoyar cada fase de la construcción, proporcionando a nuestros clientes la flexibilidad de elegir el equipo adecuado para sus proyectos.

Más de 10 años controlando la calidad de los productos

Nuestros rigurosos procesos de control de calidad se han perfeccionado a lo largo de más de 10 años, garantizando que cada equipo que producimos cumpla los estándares más exigentes. Nuestro equipo de control de calidad supervisa meticulosamente cada fase de la producción, garantizando que nuestros productos ofrezcan un rendimiento y una durabilidad constantes sobre el terreno.

Trabajadores cualificados con más de 8 años de experiencia

Nuestro equipo está formado por trabajadores altamente cualificados con más de 8 años de experiencia en el sector de la maquinaria de construcción. Su experiencia y dedicación se reflejan en la precisión y artesanía de nuestros productos, garantizando que cada detalle se ejecute a la perfección.

8 talleres, 12 líneas de producción

Con 8 talleres de última generación y 12 líneas de producción, nuestras capacidades de fabricación están diseñadas para satisfacer eficientemente demandas a gran escala. Nuestras avanzadas instalaciones nos permiten mantener un proceso de producción racionalizado, garantizando la entrega puntual de maquinaria de alta calidad a nuestros clientes de todo el mundo.

Consiga una mayor eficacia en la construcción con nuestra maquinaria diseñada por expertos

Descubra un mundo de avanzados equipos de construcción diseñados para satisfacer las exigencias de las obras modernas. Con 20 años de experiencia en el sector y un compromiso con la calidad, nuestra maquinaria está diseñada para aumentar la productividad y garantizar la fiabilidad en cada proyecto. Explore nuestra variada gama y experimente la diferencia de las soluciones diseñadas con precisión.