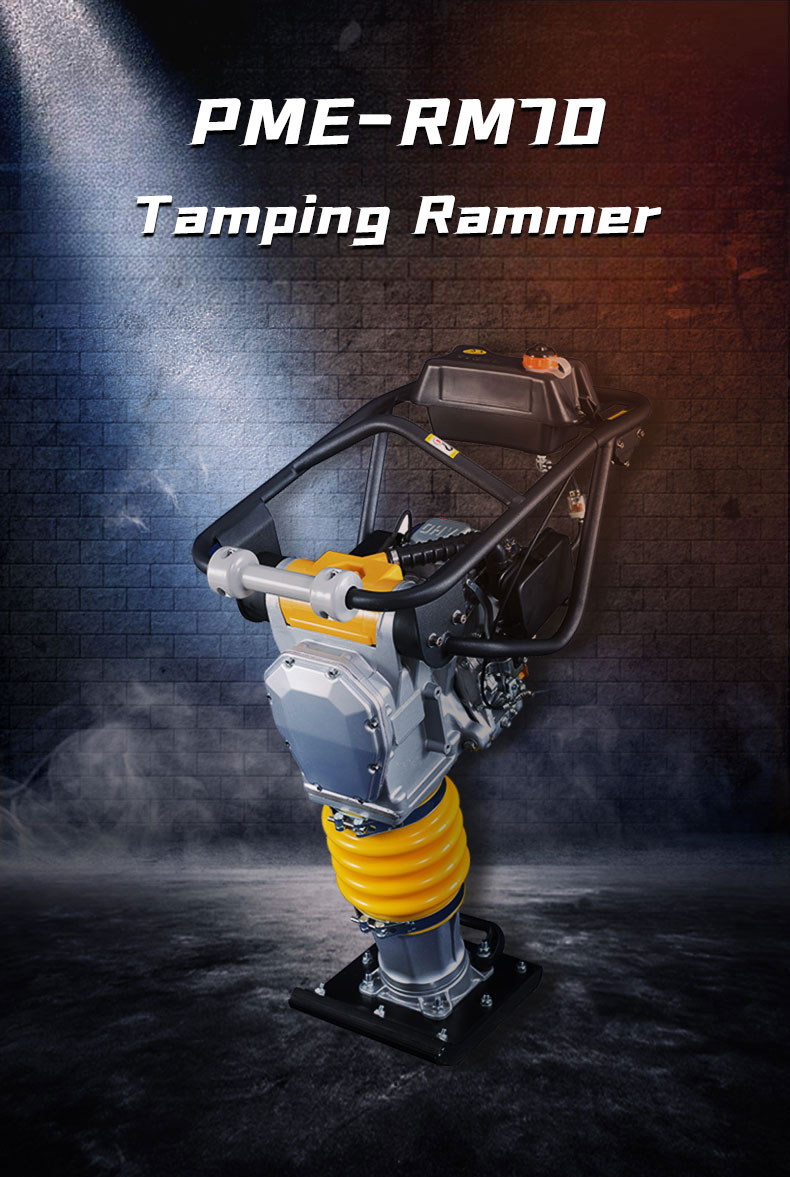

Pisón de gato PME-RM70

Cuando busque un pisón para gatos de salto, podemos ayudarle a seleccionar el más adecuado apisonador para su negocio.

Pisón de gato PME-RM70

El apisonador de salto PME-RM70 está diseñado para la compactación de suelos de alto impacto, ideal para contratistas y profesionales que realizan tareas de compactación exigentes. Con una sólida placa de 345 x 285 mm y una impresionante fuerza de apisonamiento de 14 KN, este apisonador alcanza una altura de salto de 85 mm, lo que lo hace muy eficaz para compactar suelos densos y cohesivos.

Potente rendimiento

Con una selección de motores Honda GXR120, Robin EH12-2D o Loncin LC165F-3H, la PME-RM70 garantiza un rendimiento fiable y potente. El motor de gasolina de 4 tiempos, monocilíndrico y refrigerado por aire, junto con un depósito de combustible de 2,8 l, permite largas horas de funcionamiento en proyectos exigentes. Funcionando a una frecuencia de 690 VPM, este apisonador de gatos de salto proporciona un impacto consistente y robusto para compactar suelos de forma eficiente, lo que lo hace adecuado para proyectos pesados en obras de construcción.

Aplicación versátil

La PME-RM70 está diseñada para ofrecer versatilidad, destacando en espacios reducidos donde la precisión y la potencia son esenciales. Es una solución ideal para suelos cohesivos como arcilla y limo, así como para tipos mixtos, garantizando una compactación completa en aplicaciones como zanjeo, preparación de cimientos y trabajos en tuberías. Este apisonador es un activo valioso para contratistas, servicios de alquiler y profesionales que necesitan equipos de alto impacto para tareas especializadas.

Construido para durar

La durabilidad es una característica primordial del PME-RM70, que está fabricado con materiales de primera calidad para soportar los rigores del uso intensivo en obras exigentes. Este apisonador de salto está fabricado para ofrecer un rendimiento duradero, por lo que es adecuado para aplicaciones como la preparación del subsuelo, bases de muros de contención y reparaciones de carreteras, ofreciendo resultados fiables en todo momento.

Aplicaciones

- Compactación de zanjas para la instalación de servicios públicos y tuberías

- Preparación de cimientos y zapatas

- Compactación del subsuelo y de la capa de base

- Zapatas de muro de contención

- Reparación de asfalto

- Compactación de suelos cohesivos y mixtos (por ejemplo, arcilla, limo)

- Estabilización del suelo para proyectos de paisajismo

- Compactación en espacios confinados o estrechos

Con su potente fuerza de apisonamiento, opciones de motor fiables y construcción duradera, el apisonador PME-RM70 Jumping Jack está diseñado para satisfacer las necesidades de los profesionales de la construcción y los proveedores de alquiler, ofreciendo una eficiencia y fiabilidad inigualables en la compactación del suelo.

Especificaciones

| Modelo | Pisón de gato PME-RM70 |

|---|---|

| Motor | Honda GXR120; Robin EH12-2D; Loncin LC165F-3H |

| Tipo de motor | Motor de gasolina de 4 tiempos, monocilíndrico, refrigerado por aire |

| Depósito de combustible [L] | 2.8 |

| Altura de salto [mm] | 85 |

| Frecuencia [VPM] | 690 |

| Fuerza de apisonamiento [KN] | 14 |

| Tamaño de la placa (LxA) [cm] | 345x285 |

| N.W./G.W. [kg] | 75/85 |

| Paquete (LxAnxAl) [cm] | 75x43x110 |

VENTAJA

Depósito de combustible reforzado

El depósito de combustible está fabricado con materiales resistentes a los impactos y accesorios seguros, lo que garantiza un almacenamiento fiable del combustible y evita las fugas en condiciones de trabajo exigentes.

Motor robusto

Equipada con un potente y fiable motor de marcas de renombre, que garantiza un rendimiento suave con bajo nivel de ruido, mantenimiento mínimo y eficiencia de combustible.

Sistema avanzado de absorción de impactos

El diseño amortiguador mejorado reduce significativamente las vibraciones en las manos del operador, proporcionando una experiencia de manejo cómoda y controlada.

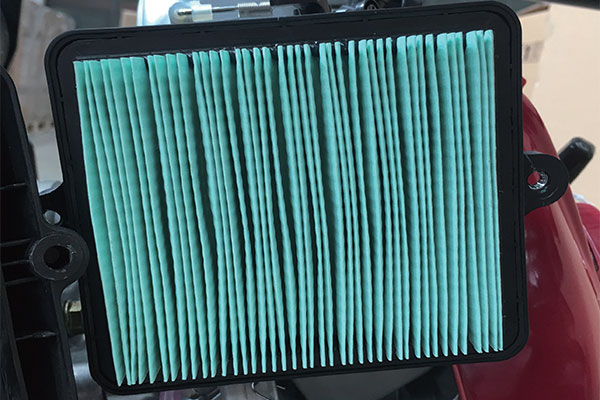

Sistema eficaz de purificación del aire

Un sofisticado sistema de filtro de aire atrapa eficazmente el polvo y los residuos, manteniendo el motor más limpio y reduciendo las necesidades de mantenimiento para prolongar la vida útil del rendimiento.

Fuelle plegable de poliuretano

El fuelle de poliuretano flexible de alta resistencia ofrece una mayor durabilidad y longevidad, resistiendo el agrietamiento y la deformación incluso en condiciones de uso intensivo.

Placa base duradera

Una placa base reforzada construida con acero de alta calidad, diseñada para ofrecer la máxima estabilidad y una eficacia de compactación óptima en diversos terrenos.

PREGUNTAS Y RESPUESTAS

Los apisonadores Jumping Jack son más eficaces en suelos cohesivos, como la arcilla, donde su gran fuerza de impacto puede lograr una compactación profunda.

Un apisonador de salto es más adecuado para espacios reducidos y suelos cohesivos, mientras que un compactador de rodillos es ideal para zonas más grandes con suelos granulares.

Algunos modelos están diseñados para minimizar las emisiones, y existen opciones eléctricas para proyectos sensibles al medio ambiente.

Los modelos eléctricos son potentes, aunque los de gas suelen ofrecer una mayor fuerza de compactación.

El uso de modelos eléctricos y de protectores auditivos con supresión de ruido puede ayudar a reducir el impacto del ruido durante el funcionamiento.

Sí, los apisonadores de salto pueden funcionar con grava, aunque los compactadores de placa podrían ser más eficaces para la grava suelta.

Otros productos similares

Sierra para cortar hormigón PME-Q400

Sierra de hormigón PME-Q350

Sierra de carretera PME-Q300

Rodillo vibratorio PME-R6000

Rodillo compactador PME-R3500

Rodillo compactador para la construcción PME-R3000

Más de 20 años de experiencia

Fabricante de maquinaria de construcción

Fabricante profesional de pequeña maquinaria de construcción, los principales productos incluyen compactador de placas, apisonadorapisonadora, sierra de piso, vibrador de hormigóngenerador, etc.

Apisonador

Los apisonadores desempeñan un papel vital en la construcción moderna, y se utilizan ampliamente por su eficacia en la compactación de tierra, grava y otros materiales granulares. Conocidos por su movimiento de alto impacto, los apisonadores estabilizan el suelo, proporcionando fuertes cimientos para carreteras, caminos y edificios, así como las superficies compactadas necesarias para diversas aplicaciones de construcción. Su potente fuerza de impacto y su versatilidad los convierten en la mejor elección tanto para contratistas como para constructores, garantizando unos cimientos fuertes y fiables en cada proyecto.

La guía definitiva de los Jumping Jack Tampers

Los apisonadores Jumping Jack, también conocidos como apisonadores o apisonadores de compactación, son potentes herramientas diseñadas para la compactación del suelo en una gran variedad de terrenos y tipos de proyectos. Su función principal es comprimir tierra, arena o grava, haciendo el suelo más estable para cimientos, carreteras y paisajismo. En esta guía, cubriremos todos los aspectos de estas herramientas indispensables, desde la comprensión de su estructura y función hasta la elección del mejor modelo para sus necesidades.

1. ¿Qué es un Jumping Jack Tamper?

Los apisonadores Jumping Jack son herramientas de compactación utilizadas principalmente en la construcción y el paisajismo para crear superficies firmes y estables. A diferencia de los compactadores de placa, que aplican una compactación uniforme en un área amplia, los apisonadores de salto son más pequeños y están diseñados para penetrar y compactar el suelo más profundamente, lo que los hace ideales para zanjas estrechas o áreas con suelos cohesivos como la arcilla.

1.1 Historia y desarrollo de los apisonadores Jumping Jack

Los apisonadores Jumping Jack evolucionaron como herramientas especializadas para hacer frente a las limitaciones de los apisonadores manuales tradicionales y los compactadores de placa mecánicos. Desarrollados originalmente para abordar trabajos que requerían una compactación intensiva y profunda del suelo, los primeros modelos eran simples dispositivos accionados por pistón. Con el tiempo, las innovaciones en el diseño del motor, la calidad de los materiales y la ergonomía dieron lugar a los apisonadores de gran eficacia que se utilizan hoy en día, convirtiéndolos en un elemento básico en la construcción.

1.2 Objeto y funciones

El objetivo principal de un apisonador de salto es producir golpes de gran impacto que condensen las capas del suelo, mejorando la estabilidad de las estructuras construidas encima. Destacan en zonas estrechas y confinadas y funcionan especialmente bien con suelos cohesivos, donde los compactadores de placa podrían no penetrar profundamente.

2. Componentes clave de un manipulador de gatos de salto

Los apisonadores Jumping Jack constan de varias piezas fundamentales, cada una de las cuales contribuye a la potente capacidad de compactación de la herramienta.

2.1 Tipos de motor

La mayoría de los apisonadores funcionan con motores de gasolina o diésel. Los apisonadores de gasolina son populares por su portabilidad y facilidad de repostaje, mientras que los modelos diésel ofrecen un par superior para trabajos pesados. Algunos modelos más nuevos utilizan incluso motores alimentados por batería, que pueden reducir las emisiones y el ruido, pero pueden ser menos potentes.

2.2 Zapata y placa de compactación

La zapata de compactación, situada en la base, es la parte que entra en contacto directo con el suelo. Esta placa pesada y duradera impulsa la fuerza de compactación en el suelo. Las zapatas varían en anchura, con zapatas más pequeñas que ofrecen una compactación precisa para zanjas y zapatas más grandes que cubren superficies más amplias.

2.3 Combustible y fuentes de energía

Aunque el gas sigue siendo el tipo de combustible más común, los apisonadores eléctricos son cada vez más populares, especialmente para proyectos en zonas sensibles al ruido o en interiores. La eficiencia del combustible es un factor crítico para quienes trabajan en grandes proyectos, ya que los costes de combustible pueden aumentar considerablemente.

3. Cómo funcionan los Jumping Jack Tampers

Los apisonadores Jumping Jack crean compactación mediante un mecanismo de percusión que golpea el suelo con movimientos rápidos y repetidos. El resultado es una capa de suelo densa y estable.

3.1 Proceso mecánico

El motor acciona un pistón que levanta y baja repetidamente la zapata de compactación. Este movimiento produce un alto nivel de energía de impacto dirigida al suelo, lo que garantiza una penetración profunda en el suelo y un aumento de la densidad.

3.2 Técnicas de compactación del suelo

Una compactación adecuada depende del movimiento constante y uniforme del apisonador. Los operadores suelen guiar el apisonador con un movimiento controlado y rítmico, evitando la compactación excesiva en una sola zona. Es esencial ajustar la velocidad en función del tipo de suelo y el contenido de humedad para obtener resultados óptimos.

4. Tipos de apisonadores

Los distintos tipos de apisonadoras de gatos de salto satisfacen diversas necesidades, con opciones basadas en el combustible, el tamaño y la potencia.

4.1 Modelos de gas frente a eléctricos

Los modelos que funcionan con gas suelen ser más robustos y pueden utilizarse en zonas remotas, mientras que los modelos eléctricos ofrecen un funcionamiento más silencioso y son adecuados para interiores o entornos con restricciones acústicas.

4.2 Modelos ligeros frente a modelos pesados

Los apisonadores ligeros son más fáciles de maniobrar e ideales para proyectos pequeños, mientras que los modelos para trabajos pesados ofrecen una mayor energía de impacto para construcciones a gran escala y tipos de suelo exigentes.

5. Aplicaciones de los apisonadores Jumping Jack

Desde la construcción hasta el paisajismo, los apisonadores de gatos de salto se utilizan ampliamente para tareas que requieren una compactación exhaustiva del suelo.

5.1 Construcción y obras viarias

En la construcción de carreteras, los apisonadores de salto crean cimientos estables, reduciendo el riesgo de agrietamiento y asentamiento del pavimento. También son indispensables para el trabajo en zanjas, ya que permiten comprimir la tierra en espacios reducidos.

5.2 Paisajismo y proyectos domésticos

Los apisonadores de gatos de salto ayudan a crear bases estables para patios, pasarelas y muros de contención. Su portabilidad y versatilidad los hacen ideales para proyectos más pequeños en los que la compactación profunda del suelo es esencial.

5.3 Aplicaciones industriales

En aplicaciones industriales, los apisonadores proporcionan una compactación crítica para tuberías, líneas eléctricas y otras infraestructuras enterradas, garantizando la durabilidad y reduciendo el riesgo de erosión del suelo.

6. Ventajas del uso de bateadoras de saltos

Estos apisonadores ofrecen varias ventajas, desde la rentabilidad hasta la facilidad de uso.

6.1 Ventajas de eficiencia y rendimiento

Los apisonadores de gato saltador proporcionan una gran energía de impacto en zonas compactas, lo que ahorra tiempo y aumenta la estabilidad de los cimientos. Su movimiento vertical también minimiza el desplazamiento de materiales, manteniendo la compactación centrada.

6.2 Rentabilidad de los grandes proyectos

Cuando se utilizan correctamente, los apisonadores de gatos de salto pueden eliminar la necesidad de compactación adicional, reduciendo los costes de mano de obra y los plazos del proyecto.

7. Comparación de los apisonadores de saltos con los compactadores de placas

Aunque ambas herramientas se utilizan para la compactación, los apisonadores de gatos de salto y los compactadores de placas sirven para fines distintos.

7.1 Ventajas e inconvenientes de cada herramienta

Los apisonadores de gatos de salto destacan en espacios reducidos y suelos cohesivos, mientras que los compactadores de placas son mejores para áreas más grandes y abiertas. Los apisonadores ofrecen más impacto por pulgada cuadrada, lo que los hace ideales para una compactación más profunda.

7.2 Elegir el equipo adecuado para el trabajo

Tenga en cuenta el tipo de suelo, el tamaño del proyecto y la accesibilidad del lugar. Para zonas grandes y abiertas, lo mejor es un compactador de placa. Para zanjas o suelos cohesivos, la mejor opción es un apisonador de salto.

8. Cómo elegir el apisonador de gatos de salto adecuado

La selección del pisón ideal depende de sus necesidades específicas y de su presupuesto.

8.1 Factores a tener en cuenta

Tenga en cuenta el tipo de motor, la eficiencia del combustible, la energía de impacto y el tamaño de la zapata. Para un uso frecuente, la durabilidad y los requisitos de mantenimiento también son factores clave.

8.2 Principales marcas y modelos

Marcas como Wacker Neuson, Multiquip y Honda ofrecen modelos de alto rendimiento. Cada marca tiene sus puntos fuertes: Wacker Neuson es conocida por su durabilidad, Multiquip por su rendimiento y Honda por su fiabilidad.

9. Manejo seguro de un manipulador de gatos de salto

La seguridad es primordial cuando se utiliza maquinaria de alto impacto, como los apisonadores de salto.

9.1 Equipo de seguridad y buenas prácticas

Los operarios deben llevar equipo de protección, incluidos guantes, protección auditiva y gafas de seguridad. Asegúrese de que el pisón está sobre un suelo estable antes de utilizarlo para evitar vuelcos accidentales.

9.2 Errores comunes que hay que evitar

Entre los errores más comunes se encuentran la compactación excesiva, que puede provocar la inestabilidad del suelo, y la manipulación inadecuada del combustible o las fuentes de energía, que pueden causar daños.

10. Consejos de mantenimiento para una mayor longevidad

Un mantenimiento adecuado puede prolongar significativamente la vida útil de un pisón de salto.

10.1 Controles e inspecciones de rutina

Inspeccione regularmente el apisonador para comprobar el desgaste de la zapata de compactación, las piezas del motor y los conductos de combustible. Comprobar el aceite y los filtros de aire antes del uso puede evitar problemas mayores.

10.2 Almacenamiento y cuidado

Almacene el pisón en un lugar seco y cubierto para evitar la oxidación. Debe vaciarse el combustible si la máquina se almacena durante periodos prolongados.

11. Solución de problemas comunes

Entender los problemas más comunes y sus soluciones puede ahorrar tiempo y dinero.

11.1 Problemas de motor y potencia

Si el motor no arranca, compruebe el nivel de combustible y la bujía. El sobrecalentamiento puede indicar un nivel bajo de aceite o una obstrucción en la entrada de aire.

11.2 Vibraciones y problemas de la placa de compactación

Las vibraciones inusuales podrían indicar la presencia de tornillos sueltos o de una zapata desgastada. Solucionar estos problemas con prontitud puede evitar daños mayores.

Conclusión

Los apisonadores Jumping Jack son herramientas esenciales para cualquiera que necesite una compactación completa del suelo en zonas estrechas o difíciles. Con una gran variedad de modelos disponibles, hay un apisonador para cada proyecto, desde la construcción pesada hasta el paisajismo doméstico. Al comprender cómo seleccionar, manejar y mantener estas máquinas, los usuarios pueden lograr resultados fiables y duraderos que apoyen unos cimientos fuertes y estables para todo tipo de estructuras.

Quiénes somos

Wuxi Pinnacle Mechanical Equipment Co., Ltd. (PME) Como empresa especializada de primera clase, servimos a clientes de todo el mundo. PME se especializa en la producción de compactador de placa, apisonador, sierra de piso, vibrador de concreto para la industria de la construcción mundial. También producimos motores, generadores y bombas de agua. Los puntos fuertes de PME se basan en nuestro fuerte equipo y ricos recursos.

Disponemos de líneas completas de producción y montaje para diferentes máquinas. Contamos con un equipo de ingenieros jefe, técnicos superiores e inspectores de control de calidad, equipados con diversos equipos de acabado, inspección de piezas de repuesto y pruebas de productos, para salvaguardar la producción y la innovación. Así, podemos controlar cada paso de la producción, desde el mecanizado de acabado de las piezas de repuesto, el corte y la soldadura de la chapa de acero, la pulverización de pintura, hasta el montaje del producto. El resultado es un control eficaz de la calidad del producto.

Con más de 20 años de experiencia exportadora, PME ha exportado a más de 68 países y regiones, incluyendo Norteamérica, Sudamérica, Europa, Sudeste Asiático, Oriente Medio y África. También formamos corporaciones estratégicas con muchas empresas multinacionales.

Fábrica

Deje que nuestra experiencia en Compactadores de Placas Forward personalizados lleve sus proyectos al siguiente nivel.

Por qué elegirnos

Fabricante profesional de maquinaria de construcción con servicio OEM

Somos un fabricante líder en el sector de la maquinaria de construcción y ofrecemos servicios de fabricante de equipos originales (OEM) de primera categoría. Nuestro compromiso con la innovación y la ingeniería de precisión garantiza que nuestra maquinaria satisfaga las necesidades específicas de nuestros clientes, proporcionando soluciones personalizadas que mejoran la eficiencia y el rendimiento en el lugar de trabajo.

20 años de experiencia en producción y exportación

Con dos décadas de experiencia en producción y exportación, nos hemos forjado una sólida reputación por suministrar equipos de construcción fiables y de alta calidad en todo el mundo. Nuestros amplios conocimientos y experiencia en el sector nos permiten comprender los retos específicos de los distintos mercados, garantizando que nuestros productos se adaptan para cumplir las normas mundiales.

Más de 20 tipos de equipos de construcción disponibles para su selección

Ofrecemos una variada gama de más de 20 tipos de equipos para obras de construcción, que satisfacen las distintas necesidades del sector. Desde maquinaria pesada hasta herramientas especializadas, nuestra gama de productos está diseñada para apoyar cada fase de la construcción, proporcionando a nuestros clientes la flexibilidad de elegir el equipo adecuado para sus proyectos.

Más de 10 años controlando la calidad de los productos

Nuestros rigurosos procesos de control de calidad se han perfeccionado a lo largo de más de 10 años, garantizando que cada equipo que producimos cumpla los estándares más exigentes. Nuestro equipo de control de calidad supervisa meticulosamente cada fase de la producción, garantizando que nuestros productos ofrezcan un rendimiento y una durabilidad constantes sobre el terreno.

Trabajadores cualificados con más de 8 años de experiencia

Nuestro equipo está formado por trabajadores altamente cualificados con más de 8 años de experiencia en el sector de la maquinaria de construcción. Su experiencia y dedicación se reflejan en la precisión y artesanía de nuestros productos, garantizando que cada detalle se ejecute a la perfección.

8 talleres, 12 líneas de producción

Con 8 talleres de última generación y 12 líneas de producción, nuestras capacidades de fabricación están diseñadas para satisfacer eficientemente demandas a gran escala. Nuestras avanzadas instalaciones nos permiten mantener un proceso de producción racionalizado, garantizando la entrega puntual de maquinaria de alta calidad a nuestros clientes de todo el mundo.

Consiga una mayor eficacia en la construcción con nuestra maquinaria diseñada por expertos

Descubra un mundo de avanzados equipos de construcción diseñados para satisfacer las exigencias de las obras modernas. Con 20 años de experiencia en el sector y un compromiso con la calidad, nuestra maquinaria está diseñada para aumentar la productividad y garantizar la fiabilidad en cada proyecto. Explore nuestra variada gama y experimente la diferencia de las soluciones diseñadas con precisión.